Understanding pgm catalytic converter prices is critical for recyclers, sellers, and refiners alike, the value hinges on market dynamics, metal content, and accurate assay. At Ledoux & Co., we recognize that fair pricing depends on knowing exactly what your converters are worth.

In this article, we first explore the market and material factors, and then explain how rigorous testing ensures transparency and confidence in pricing.

What Determines PGM Catalytic Converter Prices?

In analyzing pgm catalytic converter prices, several interrelated drivers determine their value. Below, we explore the most important factors, from raw metal markets to the physical condition of the converter itself.

Precious Metal Value (Pt, Pd, Rh)

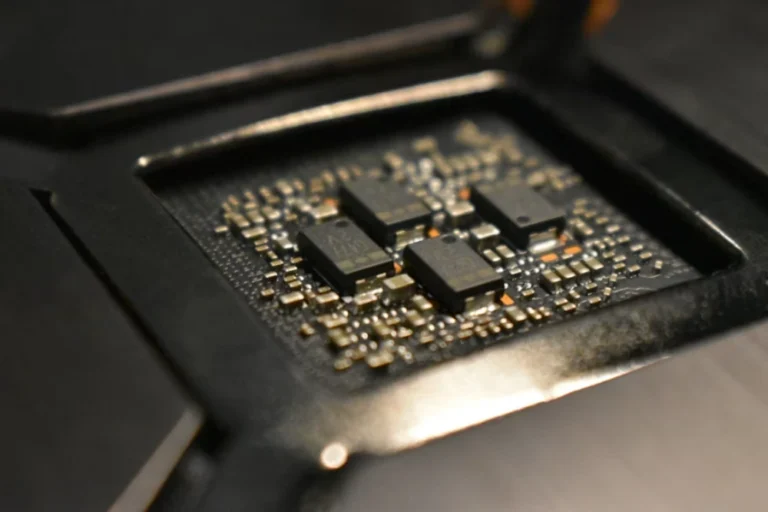

Catalytic converters contain platinum (Pt), palladium (Pd), and rhodium (Rh), collectively known as the platinum-group metals, or PGMs. The spot market value of these metals directly drives how much recyclers are willing to pay for scrap converters.

- Platinum (Pt): Platinum demand remains strong due to tight mine supply and industrial uses, including automotive applications.

- Palladium (Pd): Widely used in gasoline-powered converter designs, palladium’s value can fluctuate based on demand shifts, especially as electric vehicle adoption affects traditional internal combustion engine (ICE) volumes.

- Rhodium (Rh): Though present in only small grams per converter, rhodium is exceptionally rare, and its price is highly volatile, making it a disproportionately influential factor in scrap value.

Real‑time PGM prices are publicly available, for example via MetalsDaily, which tracks live spot quotes and helps recyclers and sellers monitor market movements.

Vehicle Type, Converter Design & PGM Loading

The make, model, and fuel type of a vehicle strongly influence how much PGM is loaded into its converter. More PGM means higher value.

- Gasoline vs. diesel vs. hybrid: Gasoline converters typically contain more rhodium and palladium; diesel or hybrid vehicles may have different PGM ratios.

- Substrate and wash‑coat: Whether the converter uses a ceramic or metallic substrate, and the thickness or surface area of the wash‑coat, affects PGM loading.

- Regulatory generation: Older vehicles or early designs may have less stringent PGM loading, while newer emission‑compliant converters often carry more metal.

- Vehicle size: Larger vehicles or trucks usually have larger converters, which may host more PGMs.

- Special cases: Low‑volume or hybrid vehicles often have higher PGM concentration per unit to meet emission regulations.

Market & Recycling Supply‑Side Dynamics

Supply‑side forces also heavily influence pgm catalytic converter prices. These include how many spent converters are available, how they are recycled, and overall market sentiment.

- End-of-life supply: When fewer cars reach end-of-life or when owners hold onto vehicles longer, the supply of scrap converters tightens.

- EV adoption: As more EVs reduce the need for traditional catalytic converters, the flow of scrap units may decline, pressuring supply.

- Regulatory changes: Emissions regulations that mandate heavier PGM loadings in new converters can increase long-term scrap value.

- Market speculation: Fluctuations in precious metal markets, driven by investor behavior, can amplify pricing spikes or dips. For example, rhodium has seen dramatic swings, influencing converter values.

Condition, Homogeneity & Ancillary Factors

The physical and logistical condition of scrap converters also plays a major role in pricing.

- Condition: Converters that are contaminated, melted, or missing substrate offer less recoverable PGM, reducing value.

- Homogeneity: When a lot contains mixed makes and models, buyers consider it riskier; homogeneous lots (same design) are more valuable.

- Lot size: Larger, bulk lots receive more favorable pricing because of economies of scale.

- Traceability and documentation: Clear chain-of-custody and purity of the material increase trust and therefore price.

- Logistics: Transportation costs, assay risk, and sample preparation all factor in. Lots with poor documentation or that are cumbersome to assay may be discounted.

Why Testing Is a Key to Fair Pricing

At a Metallurgical Testing Laboratory like Ledoux & Co., we firmly believe that testing is not just a technical step, it’s fundamental to ensuring that pgm catalytic converter prices reflect true value.

The Role of Accredited Laboratory Analysis

We are an independent testing laboratory with full ISO 17025 accreditation and ISO 9001:2015 certification, anchored in over 140 years of metallurgical expertise.

This accreditation guarantees that our methods are validated, traceable, and defensible. Commercial-grade assays delivered by a certified lab provide confidence in the reported PGM content, critical for transparent and fair pricing negotiations.

Sampling, Preparation & Analytical Methods

Accurate assay starts with how you sample the material and prepare it for analysis. At Ledoux & Co., proper procedures ensure representativeness and precision:

- Sampling methods such as decanning, crushing, or homogenizing help ensure the sample reflects the lot.

- Analytical techniques include:

- X‑ray fluorescence (XRF): Fast and non‑destructive, but typically only analyzes surface or near-surface layers.

- ICP‑OES / ICP‑MS: Involves digestion of the sample and offers precise quantification of Pt, Pd, and Rh.

- Fire assay / cupellation: Considered a gold standard, especially for trace-level analysis.

To avoid misvaluation, we pay close attention to sample size, grinding mesh size, and subsample selection to reduce bias.

How Lab Testing Translates into Better Pricing

Lab testing provides a direct, data-driven basis to derive pgm catalytic converter prices.

We report back grams of each PGM per unit or per kilogram of lot. By applying current spot market values, you can convert those grams into an accurate scrap value. This eliminates guesswork and helps sellers avoid low-ball offers based purely on visual or generic estimates.

Verified assay data reduces risk for buyers and refiners by confirming actual PGM content. Our independent, accredited reports support negotiations, financial settlements, and even regulatory or legal contexts.

How to Partner with a Lab (What to Expect)

Working with us to evaluate your converters is straightforward, here’s what the process typically looks like:

- Submission: You send samples to us and define the scope, such as “spent automotive catalyst analysis/testing,” which is a specialization of ours.

- Chain-of-custody: We maintain clear documentation so your material is traceable and auditable.

- Method selection: Together, we choose the right testing method depending on your turnaround needs and precision requirements.

- Turnaround and cost: Faster methods cost less but may be less granular; deep assays take longer but yield more precise data.

- Reporting: We deliver a detailed report, grams of Pt, Pd, Rh per unit or per lot, and an inferred economic value.

- Interpretation & next steps: We help interpret the report, calculate lot value, and recommend strategies for negotiation or sale.

By partnering with us, you gain confidence, mitigate transaction risk, and unlock the true value in your converter inventory.

Unlock Full Value Through Transparent Analysis with Ledoux

At Ledoux & Co., our 140‑plus years of metallurgical testing expertise, combined with ISO 17025 accreditation, offer you a trustworthy, independent pathway to value your catalytic converter materials.

If you’re looking to maximize pgm catalytic converter prices, contact our team today, submit your samples, request a quote, and take control of your pricing with the confidence that only accurate, accredited testing can provide.