Rare earth element mining companies operate in a technically demanding sector where success depends on more than ore extraction. Transforming complex, often low-grade materials into marketable rare earth products requires careful metallurgical design, precise processing, and reliable data.

At Ledoux & Co., we support these projects with independent, ISO-accredited metallurgical testing and defensible analytical data, helping companies reduce risk and make informed decisions from evaluation through scale-up.

The Hidden Challenges of Rare Earth Element Mining Companies

Rare earth element mining companies face challenges related to mineralogical variability, chemical separation difficulty, and strict regulatory constraints.

Complex and Variable Ore Mineralogy

Ore mineralogy is one of the primary factors controlling recovery and processing cost in rare earth mining operations.

Rare earth elements (REEs) occur in diverse mineral forms such as bastnäsite, monazite, xenotime, and ionic clays. Each mineral responds differently to crushing, grinding, leaching, and separation, requiring tailored metallurgical approaches rather than standardized flowsheets.

Small changes in mineralogy can significantly impact recoveries and downstream processing costs. For example, variations in grain size, mineral associations, or gangue composition may alter reagent consumption or separation efficiency. Without accurate mineralogical characterization, projects risk designing processes that fail under real operating conditions.

Reliable laboratory characterization is essential before scaling any process. Detailed mineralogy, phase identification, and liberation analysis provide the foundation for sound metallurgical decisions and realistic economic modeling.

Metallurgical Processing and Separation Challenges

Rare earth elements have very similar chemical properties, making separation difficult and technically intensive. Unlike metals that can be recovered through relatively simple concentration steps, REEs often require complex chemical processing to isolate individual elements.

Processing frequently involves multi-stage flotation, acid or alkaline leaching, solvent extraction, or ion exchange circuits. Each step must be carefully designed and tested, as inefficiencies compound across the flowsheet. Poorly designed metallurgical flowsheets lead to low recoveries, high reagent consumption, and excessive waste generation.

Bench-scale and pilot-scale testing are critical to validate assumptions and optimize operating parameters. These test programs generate the data needed to understand recovery trade-offs, reagent selection, and impurity behavior before committing to large capital investments.

Radioactive and Impurity Management

Many rare earth ores contain naturally occurring thorium and uranium, creating regulatory, environmental, and handling challenges. These materials are classified as technologically enhanced naturally occurring radioactive materials (TENORM) and require careful management throughout processing and disposal.

In addition to radioactive elements, impurities such as iron, aluminum, phosphorus, and silica complicate refining and product quality. These impurities can interfere with solvent extraction circuits, reduce separation efficiency, or limit market acceptance of final products.

Accurate impurity analysis is required to design safe, compliant processing routes. Independent laboratories help ensure unbiased and defensible data that can withstand regulatory scrutiny and support environmental permitting.

Why Reliable Technical Expertises Are Critical for Rare Earth Projects

Reliable technical partners are critical for rare earth projects because they provide independent data needed to validate metallurgical assumptions, reduce processing risk, and support investment decisions. Without unbiased testing and accurate analysis, rare earth element mining companies face a higher likelihood of costly redesigns, regulatory setbacks, or project failure during scale-up.

Importance of Accurate and Representative Sampling

Representative sampling is essential for generating metallurgical data that accurately reflects real-world processing performance.

Inaccurate sampling leads to misleading assay results and flawed process design. Rare earth ores often exhibit significant heterogeneity, with uneven distribution of valuable minerals and impurities across a deposit.

Representative sampling ensures that metallurgical test results reflect real-world performance rather than isolated anomalies. Proper sample preparation, including size reduction, splitting, and homogenization, is essential to maintain data integrity throughout testing programs.

Independent laboratories like Ledoux reduce bias in sampling and reporting. By separating analytical work from operational pressures, third-party testing provides results that stakeholders can trust.

Metallurgical Testing and Process Development

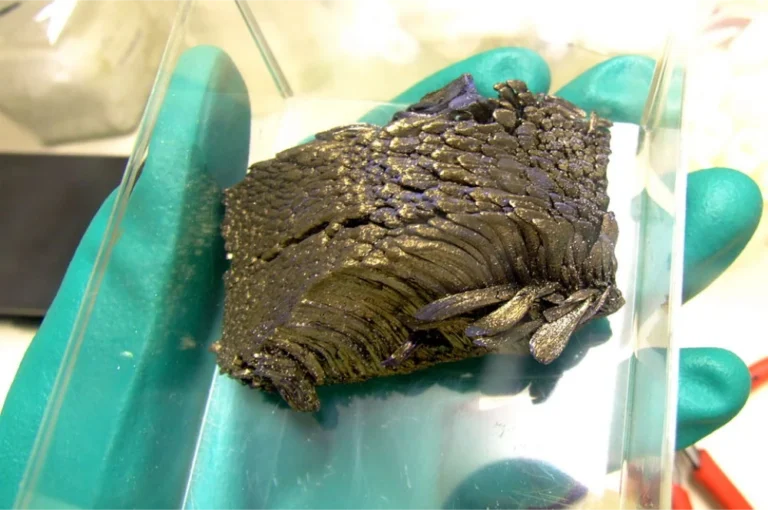

Metallurgical testing validates recovery assumptions before major capital investment. Comprehensive programs typically include mineralogical analysis, flotation testing, leaching studies, solvent extraction trials, and impurity removal evaluations.

Process development supports scale-up decisions and economic modeling. Data generated during test work informs equipment selection, reagent consumption estimates, and operating cost projections, all of which feed into feasibility studies.

Data-driven decisions help prevent costly redesigns later in the project lifecycle. Early identification of metallurgical constraints allows companies to refine project scope or adjust development strategies before financial exposure increases.

Project De-Risking Through Independent Data

Lenders, investors, and off-take partners require defensible metallurgical data to assess project viability. Unsupported recovery claims or internally generated results often fail to meet due diligence standards.

ISO-accredited laboratories provide traceability, quality assurance, and documented methodologies. Independent results support feasibility studies, regulatory submissions, and commercial negotiations by demonstrating technical credibility.

De-risking improves project credibility and long-term viability. Reliable data builds confidence among stakeholders and increases the likelihood of successful project financing and execution.

Why Ledoux is a Reliable Partner for Rare Earth Element Mining Companies

Rare earth element mining companies require partners with both technical depth and proven independence. At Ledoux & Co., we combine over a century of experience with modern analytical capabilities to support complex rare earth projects.

Independent, ISO 17025 Accredited Metallurgical Testing

We are an independent metallurgical laboratory established in 1880, with a long history of supporting mining and materials industries. Our ISO 17025 accreditation ensures accuracy, repeatability, and defensible results across all analytical services.

We provide commercial-grade assays suitable for financial, regulatory, and contractual decisions. Our independence ensures unbiased results free from operational influence, giving stakeholders confidence in the data used to guide critical decisions.

Advanced Analytical Capabilities for Rare Earth Processing

We support rare earth projects through precise elemental and impurity analysis tailored to complex REE systems. Our techniques include ICP analysis, wet chemistry, fire assay where applicable, and detailed material characterization.

Accurate impurity data supports metallurgical flowsheet design by identifying potential processing challenges early. Our results help optimize recovery, improve separation efficiency, and enhance final product quality to meet market specifications.

Reducing Risk Through Experience and On-Site Support

Our team understands the operational and financial risks associated with rare earth processing and material handling. We offer on-site representation to help ensure proper sampling, weighing, and chain-of-custody procedures at mines, plants, and ports.

Accurate documentation supports compliance and dispute resolution across the supply chain. We treat client materials as if they were our own, recognizing that trust and accountability are central to long-term partnerships.

Key Takeaways

Accurate metallurgical testing and reliable data are essential to reduce risk and improve outcomes for rare earth projects.

At Ledoux & Co., we provide independent, ISO-accredited analysis for rare earth element mining companies, backed by over 145 years of experience. Partnering with us strengthens your company with trusted metallurgical expertise.

FAQs

Rare earth element mining companies often face recurring technical and commercial questions as projects advance. The following FAQs address common concerns encountered during rare earth project development.

1. How early should metallurgical testing begin in a rare earth project?

Testing should begin as soon as representative samples are available to identify processing risks before significant capital is committed.

2. Why is independent laboratory testing important for investors?

Independent data reduces bias and provides defensible results that meet due diligence and financing requirements.

3. Can metallurgical issues be resolved after a project is built?

While possible, late-stage fixes are costly and disruptive, making early testing far more effective for risk reduction.