How are rare earth elements mined for industrial use? Rare earth elements are mined through a multi-stage process involving ore extraction, mineral concentration, chemical separation, and analytical validation to produce usable materials. These materials underpin modern energy, electronics, transportation, and advanced manufacturing.

Understanding how rare earth elements are mined helps buyers, processors, and manufacturers manage risk and ensure material reliability.

Why Rare Earth Elements Matter In Modern Manufacturing

Rare earth elements (REEs) include 17 metals: the 15 lanthanides plus scandium and yttrium. While not geologically scarce, economically concentrated deposits are limited.

REEs are mined because they deliver unique magnetic, optical, catalytic, and electrochemical properties that cannot be easily substituted.

High-strength permanent magnets, phosphors, polishing powders, catalysts, and advanced alloys all depend on REEs. Even trace amounts can dramatically improve material performance, efficiency, and durability.

As clean energy systems, electric vehicles, and advanced electronics expand, the industrial importance of REEs continues to grow.

Types Of Rare Earth Deposits Around The World

How are rare earth elements mined depends heavily on deposit type, mineralogy, and geographic constraints. Different ore bodies require distinct mining, processing, and regulatory strategies.

Common Rare Earth Ore Types

Rare earth elements occur in several distinct geological formations, each with different processing, regulatory, and commercial implications.

- Bastnäsite: Bastnäsite is the primary commercial source of light rare earth elements (LREEs). It is commonly mined through open-pit operations and contains relatively low radioactivity, simplifying permitting and waste handling.

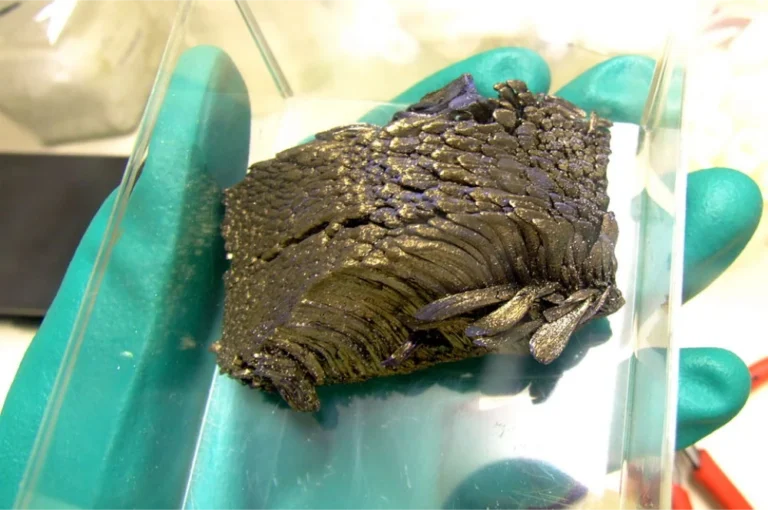

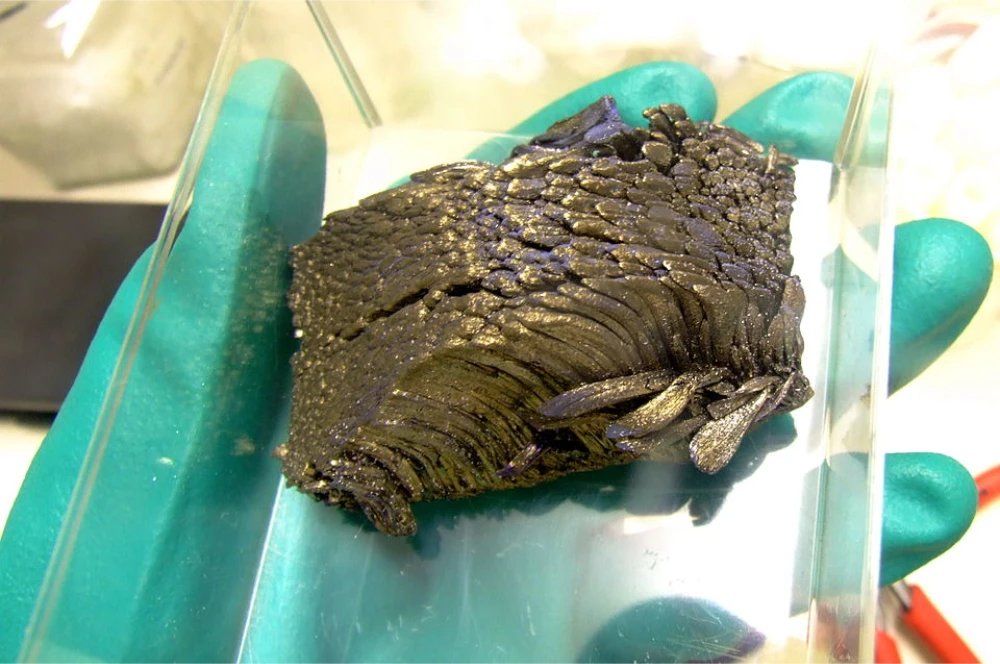

- Monazite: Monazite is rich in LREEs but often contains thorium and uranium. It is typically recovered as a byproduct of mineral sands processing and requires strict regulatory controls due to radioactive content.

- Ion-Adsorption Clays: Found mainly in southern China, these low-grade deposits are easier to chemically leach and are a key source of heavy rare earth elements (HREEs).

Global Distribution Of Rare Earth Deposits

China, the United States, and Australia are major producers. China dominates global separation and refining capacity, creating supply chain concentration risk. Environmental regulations and permitting timelines significantly influence project viability.

How Are Rare Earth Elements Mined?

How rare earth elements are mined involves sequential physical and chemical steps designed to isolate chemically similar elements. Each phase introduces technical, environmental, and analytical challenges.

Mining Methods Used For Rare Earth Elements

The choice of mining method depends on deposit depth, grade, geology, and environmental constraints.

- Open-Pit Mining (High-Volume Surface Extraction): Open-pit mining is used for shallow, laterally extensive deposits and allows efficient removal of large ore volumes. While cost-effective, it requires careful land reclamation and environmental management to mitigate surface disturbance.

- Underground Mining (Selective Deep Extraction): Underground mining is applied to deeper or structurally confined deposits where surface mining is impractical. This method reduces surface impact but involves higher capital costs, operational complexity, and safety requirements.

- In-Situ Leaching (Low Surface Impact Recovery): In-situ leaching dissolves rare earth elements directly within the ore body using controlled chemical solutions. It minimizes physical excavation but demands precise monitoring to prevent groundwater contamination and ensure controlled reagent recovery.

Crushing, Grinding, And Beneficiation

Extracted ore is crushed and ground to liberate REE-bearing minerals. Beneficiation techniques, such as flotation, gravity separation, and magnetic separation, increase REE concentration before chemical processing. Accurate sampling at this stage is essential for valuation and downstream decisions.

Chemical Processing And Separation

Concentrates are chemically cracked using acids or alkalis to dissolve REEs into solution. Solvent extraction then separates individual elements. Final outputs are typically rare earth oxides (REOs), which serve as feedstock for metals, alloys, and industrial products.

Environmental And Technical Challenges In Rare Earth Mining

How are rare earth elements mined must account for environmental risk and processing complexity. Poor controls can lead to regulatory failures, material losses, and commercial disputes.

Environmental Considerations

Chemical reagents used during processing generate large volumes of waste, including tailings and spent solutions. Some ores contain radioactive byproducts that require controlled handling and long-term storage.

Effective tailings management is essential for environmental protection and regulatory compliance. Standards and enforcement levels vary significantly by region, influencing project feasibility.

Processing And Quality Risks

Incomplete digestion during chemical processing can lead to underreported REE values. Variable mineralogy complicates separation and recovery, particularly for HREEs. Poor sample preparation or analytical bias can skew results, leading to mispricing and disputes.

Many commercial conflicts in rare earth markets stem from inconsistent or non-independent analytical data.

How Accurate and Independent Testing Reduces Risk In Rare Earth Projects

How rare earth elements are mined successfully depends on data quality at every stage. Independent testing ensures confidence in valuation, compliance, and performance.

Critical Testing Points Along The Value Chain

Raw ores require compositional screening to determine economic potential. Concentrates need grade verification before chemical processing.

Mixed REE products demand precise multi-element analysis, while final oxides and alloys require confirmation of purity and specification compliance. Each stage depends on accurate, reproducible data.

Risks Of Inaccurate Or Non-Independent Data

Inaccurate data can result in misaligned pricing, settlement errors, and reduced processing yields. It may also trigger contract disputes between buyers and sellers or lead to regulatory non-compliance. Independent laboratories reduce these risks by providing unbiased, technically defensible results.

How Ledoux Supports Rare Earth Mining And Processing

How are rare earth elements mined with commercial confidence? By integrating independent, ISO-accredited testing throughout the value chain, we help clients manage complexity and risk.

What We Test

We analyze ores, concentrates, and intermediates, as well as mixed rare earth materials requiring full elemental breakdown. Our capabilities extend to separated rare earth oxides, metals, alloys, industrial products, catalysts, and recycled materials.

How We Deliver Accurate Results

Our ISO 17025–accredited laboratory processes ensure technical rigor and traceability. We use ICP-OES and ICP-MS with optimized digestion protocols, supported by NIST-traceable quality controls. When standard methods fall short, we develop custom approaches for complex matrices. All results are independently reported for commercial use.

Key Takeaways

Rare earth mining is a technically demanding, multi-stage process with significant analytical risk. Each step, from ore to oxide, requires precise control and verification.

Independent ISO-accredited testing supports fair valuation, compliance, and operational confidence. We help clients move securely from raw material to finished product. Partner with Ledoux & Co. for reliable rare earth elements analysis and testing.

FAQs

Understanding how rare earth elements are mined often raises practical questions about technology, risk, and supply. The following FAQs address common concerns from an industrial and commercial perspective.

1. Are rare earth elements environmentally hazardous?

The elements themselves are not highly toxic, but their mining and processing can generate hazardous waste. Environmental risk depends largely on waste management and regulatory controls.

2. Which rare earth elements are most valuable?

Heavy rare earth elements such as dysprosium and terbium are typically more valuable due to scarcity and demand in high-performance magnets.

3. How does testing impact rare earth pricing?

Accurate testing determines payable content and purity, directly influencing pricing and settlement between buyers and sellers.