Computer precious metal recovery is the process of identifying, testing, and reclaiming valuable metals from discarded computer equipment and electronic scrap.

As electronics proliferate globally, these materials have become an important secondary source of precious and base metals. Accurate testing and metallurgical expertise are essential to ensure efficient recovery and fair commercial settlement.

Why Computer Scrap Is Rich In Valuable Precious Metals

Computer precious metal recovery begins with understanding why electronic scrap contains meaningful concentrations of valuable metals.

Where Precious Metals Are Found In Computer Scrap

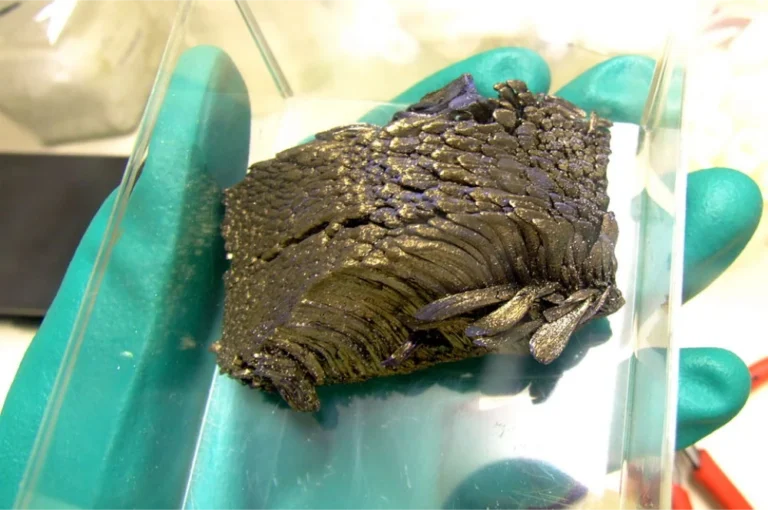

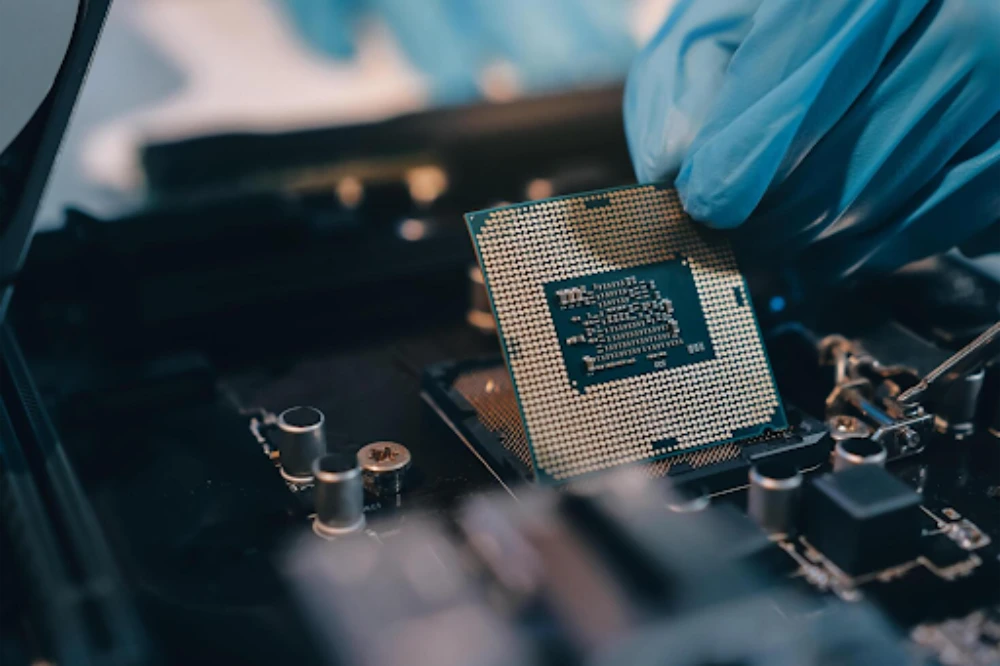

Printed circuit boards (PCBs) represent the highest-value fraction of computer scrap because they concentrate multiple precious and base metals in a compact form. PCBs are engineered to manage conductivity, heat, and durability, making them a primary focus in recovery programs.

Gold is commonly found in connectors, edge fingers, and contact points due to its excellent conductivity and corrosion resistance.

Silver appears in solder, switches, and conductive pathways, where reliability and electrical performance are required.

Palladium and other platinum group metals (PGMs) are present in multilayer ceramic capacitors and specialized components designed for stability under high temperatures.

Copper acts as both a carrier metal and a recovery driver, often determining the overall economics of processing computer scrap.

Why E-Waste Recycling Is Increasing Globally

The rapid growth of consumer electronics and shorter product life cycles have dramatically increased electronic waste volumes worldwide. Environmental regulations and extended producer responsibility programs are pushing organizations toward responsible recycling and material recovery.

Rising precious metal prices further support the economics of recovery, making electronic scrap an attractive secondary resource. Recovering metals from e-waste also reduces dependence on primary mining, which carries higher environmental and social costs.

Differences Between Consumer And Industrial Computer Scrap

Consumer electronics typically contain lower precious metal concentrations but are generated in very high volumes, making aggregation critical.

In contrast, industrial computers, servers, and networking equipment often contain higher precious metal content per unit.

Legacy equipment may include thicker gold plating and higher-grade components compared to modern devices. Effective sorting strategies, by type, age, and application, significantly improve recovery efficiency and downstream processing outcomes.

Maximizing Value Through Accurate Precious Metal Recovery

Computer precious metal recovery only delivers full value when metals are accurately identified, quantified, and processed.

Challenges In Recovering Precious Metals From Computer Scrap

Electronic scrap is highly heterogeneous, with significant variability between lots and even within individual units. Precious metals are typically present at low concentrations relative to base metals, increasing the risk of analytical and processing losses.

Without proper metallurgical controls, recovery processes may result in metal losses or incomplete extraction.

Additionally, chemical recovery methods require strict environmental and safety management to meet regulatory expectations.

The Cost Of Inaccurate Or Incomplete Recovery

Inaccurate testing or incomplete recovery can lead to undervalued material and direct financial losses for recyclers and suppliers. Disputes often arise between recyclers, refiners, and material owners when metal accounting is unclear or inconsistent.

Inefficient processing routes increase operational costs and may expose organizations to regulatory and reporting risks. Over time, these issues erode trust across the supply chain.

Why Accurate Analysis Is Critical Before Recovery

Accurate analysis determines the true precious metal content and commercial value of electronic scrap. Reliable data supports fair settlements, informed financial decisions, and transparent reporting.

Precise testing also guides the selection of appropriate recovery and refining methods, reducing unnecessary processing steps and minimizing losses.

The Role Of Assay And Chemistry In Precious Metal Recovery

Computer precious metal recovery relies on robust analytical chemistry and metallurgical assay techniques.

Why Sampling And Preparation Matter

Electronic scrap is inherently heterogeneous, making representative sampling one of the most critical steps in analysis. Poor sampling practices can introduce bias and lead to inaccurate results that do not reflect the true composition of the material.

Proper grinding and homogenization improve analytical accuracy by ensuring uniform distribution of metals within the sample. Adequate sample size is also essential to capture variability and support defensible results.

Common Analytical Errors In Electronic Scrap Testing

Over-reliance on X-ray fluorescence (XRF) screening can lead to misleading conclusions when used without confirmatory methods. Poor sample homogeneity further compounds analytical uncertainty.

Inadequate digestion or dissolution during wet chemistry preparation can result in incomplete metal recovery at the analytical stage. The absence of quality control checks, such as blanks and certified reference materials, undermines data integrity.

Why Commercial-Grade Assays Matter

Commercial-grade assays are used in financial settlements, arbitration, and contractual agreements. These assays require repeatability, traceability, and adherence to recognized standards.

NIST-traceable reference materials and compliance with ISO 17025 requirements ensure analytical credibility. Such rigor provides confidence across global supply chains and high-value transactions.

How We Support Computer Precious Metal Recovery At Ledoux & Co.

At Ledoux & Co., computer precious metal recovery is supported by independent testing, rigorous methodology, and decades of metallurgical expertise.

Our Expertise In Electronic Scrap And Precious Metals Analysis

We bring over 145 years of experience in metallurgical testing and precious metals analysis. Our laboratory is ISO 17025-accredited and ISO 9001:2015-certified, reflecting our commitment to quality and technical excellence.

Our specialized electronic scrap analysis services provide unbiased, commercially accepted results trusted by recyclers, refiners, and material owners worldwide.

Supporting Chemical Recovery And Refining Decisions

Our data-driven approach supports informed recovery and refining strategies tailored to specific material streams. Accurate metal accounting helps recyclers and refiners optimize processes while minimizing losses.

We also provide on-site representation to reduce risk during high-value processing and ensure transparency at critical stages. Our results are relied upon across global supply chains.

On-Site Representation For Risk Mitigation

Independent oversight of weighing and sampling reduces the potential for losses and disputes during material transfers. Our representatives provide transparent documentation and real-time verification.

This level of oversight delivers peace of mind when managing high-value electronic scrap and recovery campaigns.

Long-Term Partnerships With Recovery Stakeholders

We support continuous improvement programs by adapting testing methodologies to evolving materials. Our consistent, reliable data enables long-term performance tracking and optimization.

As a trusted technical partner, we help stakeholders navigate complexity with confidence and clarity.

Key Takeaways

Computer precious metal recovery transforms electronic scrap into measurable value when tested and recovered properly.

At Ledoux & Co., we deliver reliable data that supports recovery, refining, and settlement decisions. Partner with us to bring accuracy, clarity, and confidence to your electronic scrap recovery program.

FAQs

Computer precious metal recovery often raises technical and commercial questions for recyclers and material owners.

1. Why is laboratory testing necessary before recovery?

Laboratory testing establishes accurate metal content, which is essential for fair valuation, process selection, and commercial settlement.

2. Can XRF alone determine precious metal value?

XRF is useful for screening but cannot replace full laboratory analysis for accurate, commercial-grade results.

3. What role does ISO 17025 play in testing?

ISO 17025 accreditation confirms technical competence, traceability, and quality control in laboratory analysis.

4. How do recovery programs reduce environmental impact?

Recovering metals from e-waste lowers demand for primary mining and supports responsible materials management.