Understanding the difference between loss on drying and loss on ignition is critical in catalyst analysis and precious metal analysis. Even slight variations in weight measurement can lead to significant financial and technical outcomes.

This article explains what LOD and LOI mean, how they differ, why they matter in precious metals analysis, and how we at Ledoux & Co. ensure accuracy.

What Is LOI (Loss on Ignition)

Loss on Ignition (LOI) is a common analytical technique in inorganic chemistry and material science.

LOI analyzes the weight loss of an example by heating it intensely until volatile and decomposable components are completely eliminated and the mass of the sample is constant.

- LOI encompasses combined water (hydrates), carbonates (evolution of CO₂), organic matter, and other volatile substances.

- The temperature range under normal conditions is material-dependent but typically several hundred to more than a thousand degrees Celsius.

- The test may be conducted under varying atmospheres (air, inert, or controlled gas conditions) because the chemical environment dictates whether oxidation, decomposition, or combustion will occur.

- LOI is most valuable in determining the percentage of weight of a material that derives from materials that would not survive high-heat industrial processing like smelting.

By adding a greater context of volatile and break-down contents, LOI is an essential tool in industries required to measure total loss on heating, burning, or refining.

What Is LOD (Loss on Drying)

Loss on Drying (LOD) is a test focused on measuring moisture and light volatile content removable under controlled drying conditions without ignition. It is less extreme than LOI and is intended to assess water and low-boiling volatiles that can affect weight measurements.

- LOD includes free water, some bound water, and certain volatile solvents depending on the method applied.

- Drying temperatures are lower than drying temperatures for LOI and are carefully selected to prevent decomposition of the material.

- The sample is dried to constant weight, removing all surface moisture and easily removable volatiles.

- LOD provides useful information about distortion of analytical or financial analyses by environmental moisture or by solvent residues.

Because it avoids extreme heat, LOD does not decompose more stable compounds.

In pharmaceutical, catalyst, or pure metal industries, this accuracy ensures correct computation of volatile mass without compromising the base material.

The Difference Between LOI vs LOD

The terms LOI and LOD are sometimes used interchangeably, but they measure distinct properties.

What Each Includes/Excludes

LOI measures a broader set of volatile and decomposable components: hydrates, carbonates, organic matter, and other substances that react or volatilize at high heat.

In contrast, LOD is more selective. It focuses on water, moisture, and light volatiles, but does not break down chemically stable compounds. This difference makes each method suitable for specific applications.

Temperature & Method Differences

LOI is conducted at significantly higher temperatures, often reaching ignition or combustion conditions. These temperatures lead to decomposition of material and complete release of volatile content.

LOD, however, occurs under conditions of controlled drying, roughly 200 °C or less, enough to drive off water and solvents but not enough to destabilize organics or carbonates.

Atmosphere matters: LOI can depend on oxidative atmosphere, while LOD avoids reactivity in an attempt to preserve chemical structures.

Impact on Mass Loss & Reporting

Because LOI removes more material, the mass loss is usually greater than LOD for the same sample. The differences are critical for reporting results, since purity and assay values may be calculated on a dry or volatile-free basis rather than the “as received” weight.

Use Cases: When to Use Each

LOD is preferred when it requires moisture and solvents measurement alone without any changes to the chemical composition of the sample. It is ideal in pharmaceutical analysis, catalyst monitoring, and other contexts where water content must be quantified precisely.

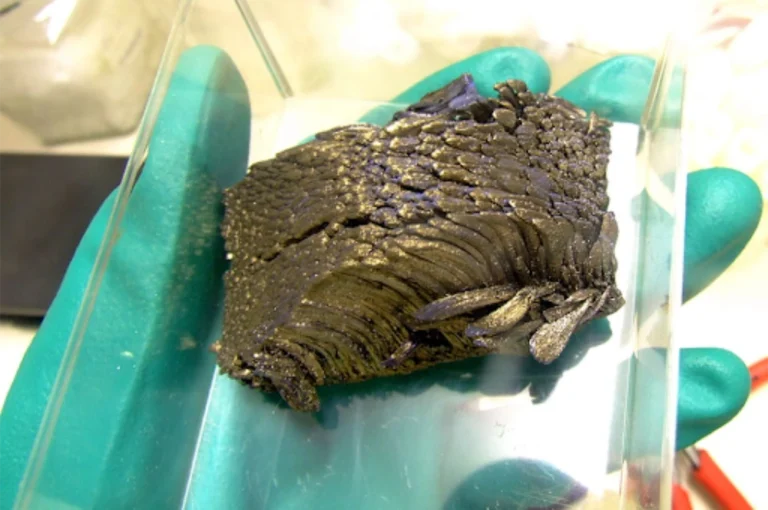

On the other hand, LOI is necessary when complete estimation of volatile loss is required, including organic matter, carbonates, and hydrates. It is especially helpful in cement, ceramics, metallurgy, smelting, and catalyst recovery, where there is a need to identify high-temperature behavior.

Many contracts and industry standards specifically require either LOI or LOD measurements, and sometimes both, to guarantee transparency and fairness in trade and analysis.

Why Are They Important in Precious Metals Analysis?

For LOI and LOD of precious metals, catalysts, and similar materials, these are critical parts of accurate valuation and technical evaluation.

Here’s why they matter:

- Financial / Valuation Implications: Moisture and volatiles increase sample weight but contribute no precious metal value. Without correcting for LOI/LOD, clients risk overpayment or undervaluation. Accurate corrections ensure financial fairness.

- Accuracy & Quality of Assay: Chemical procedures like fire assay, ICP, or XRF demand meticulous preparation. Volatiles and moisture can contaminate results. Knowing LOD and LOI assures true baseline conditions.

- Regulatory/Compliance/Contractual Requirements: Many accreditations demand volatile-free reporting or explicit LOI/LOD results. Document clarity gives confidence to regulators, traders, and insurers.

- Technical Performance & Process Outcomes: In smelting or catalyst processing, volatile and combustible content impacts furnace behavior. Off-gassing, inefficiency, or defects result from high LOI. Reliable LOI data prevents costly technical issues.

Why Ledoux & Co. is Trusted Partner for Precious Metals Analysis

At Ledoux & Co., we combine decades of experience with stringent technical requirements to offer reliable LOI and LOD testing.

Why Ledoux is your reliable partner for your analysis:

- Accreditation & Technical Expertise: We hold ISO 17025 accreditation and ISO 9001:2015 certification, demonstrating adherence to internationally recognized quality and technical standards.

- Methods & Lab Capabilities: Our facilities are equipped with precision drying ovens, high-temperature furnaces, and advanced thermogravimetric analyzers. We apply controlled atmospheres, repeated weight checks, and constant-mass verification to ensure accuracy.

- Transparent Reporting & Client Support: We clearly indicate in our reports whether results are expressed on an “as is,” dry, or ignited basis, giving clients the clarity they need for decision-making.

- Minimizing Risk & Maximizing Value: Proper accounting for LOI and LOD minimizes risks of overpayment, failure to comply, and technical ineffectiveness in downstream processes.

Our services go beyond testing, we assist customers in interpreting data and utilizing it to maximize business results.

Ensuring Confidence in Your Assays with Ledoux & Co.

The difference between loss on drying and loss on ignition goes beyond technicality, calculating inaccurately has an immediate impact on financial performance, regulatory compliance, and process efficiency.

At Ledoux & Co., we apply internationally accredited methods to ensure your results are accurate, understandable, and auditable. Through our services, clients reduce risk and optimize value per transaction.

Contact us today and see how we can assist you with trusted LOI and LOD analysis for your assay requirements!