Understanding how to identify iridium is critical for anyone handling scrap metals, jewelry, or industrial waste. Iridium is one of the rarest elements in the world, dense, corrosion-resistant, and vital across industries from electronics to high-temperature manufacturing.

Despite its value, iridium often goes undetected or is mistaken for similar-looking metals like platinum. This misidentification can lead to missed recovery opportunities and undervalued materials.

At Ledoux & Co., we help clients confirm metal content with ISO 17025-accredited testing. With over 140 years of metallurgical precision, our lab specializes in accurate rare metal analysis, including iridium, to protect your bottom line.

What Is Iridium? Properties, Uses, and Where It’s Found

Iridium is a platinum-group metal (PGM) known for its exceptional hardness, chemical inertness, and resistance to extreme temperatures. It ranks as one of the densest elements, with a melting point of 2,446°C (4,435°F) and a brilliant silvery-white appearance.

Due to these properties, iridium is used in:

- High-temperature applications, such as spark plugs, crucibles, and aerospace components

- Jewelry and watchmaking, often alloyed with platinum for added strength

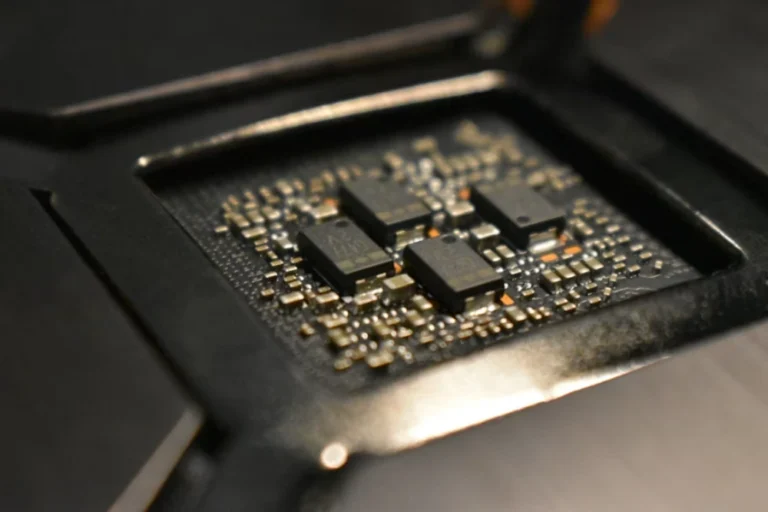

- Electronics and semiconductors, including electrical contacts and thin-film coatings

- Catalytic converters, especially in high-performance or fuel cell systems

While pure iridium is rare in consumer products, it’s commonly encountered in:

- Mixed metal scrap from electronic waste

- Old jewelry and vintage alloys

- Spent automotive and industrial catalysts

- Chemical processing equipment used in corrosive environments

Its resistance to corrosion often preserves its integrity, even in degraded or aged materials, making how to identify iridium especially important during material recovery or recycling efforts.

Visual Clues: How to Identify Iridium Properly

In field conditions where laboratory tools aren’t available, professionals often rely on visual and physical cues to begin assessing unknown metals. While iridium is difficult to distinguish without instrumentation, several characteristics can suggest its presence:

Appearance and Color

Iridium has a bright silvery-white hue, similar to platinum but often slightly whiter and more reflective. It does not tarnish or oxidize, even under harsh conditions, which is a clue to its chemical stability.

Weight and Density

With a density of 22.56 g/cm³, iridium is noticeably heavier than most metals of similar size. A piece of iridium alloy will feel exceptionally dense in hand, more so than palladium or white gold.

Hardness and Wear Resistance

Iridium is extremely hard, among the hardest of all metals. Items containing iridium may show little surface wear even after extended use. In jewelry, for example, iridium alloys resist scratching far more effectively than standard platinum.

Non-Magnetic Behavior

Like most PGMs, iridium is non-magnetic. A simple magnet test won’t confirm its identity, but it can help eliminate ferrous lookalikes.

While these cues are useful for preliminary screening, visual inspection alone is insufficient. Accurately identifying iridium, particularly in complex alloys or degraded scrap, requires laboratory analysis.

Testing Methods: How to Identify Iridium Accurately

Visual inspection can offer clues, but iridium’s accurate identification requires controlled testing conditions and specialized instrumentation. Its rarity and value demand precise verification, especially in recycled materials, catalysts, or high-value alloys.

Here are the most reliable methods used to identify iridium with confidence:

X-Ray Fluorescence (XRF) Spectrometry

XRF is a non-destructive method ideal for identifying and quantifying iridium in solid metal samples. It works by directing X-rays at a sample and analyzing the secondary emissions to determine elemental composition.

Use Case: Jewelry, electronics, mixed scrap

Benefit: Fast, accurate screening with no material loss

Ledoux Insight: Our portable and lab-grade XRF instruments are regularly calibrated against NIST-traceable standards for accuracy.

Inductively Coupled Plasma (ICP) Analysis

ICP techniques, including ICP-OES and ICP-MS, offer highly sensitive, multi-element detection in liquid samples. This method is particularly effective for identifying trace amounts of iridium in complex matrices.

Use Case: Catalysts, e-waste, chemical residues

Benefit: Detection at parts-per-billion (ppb) levels

Ledoux Insight: We use ICP as part of our ISO 17025-accredited protocols for precise trace metal identification and quantification.

Fire Assay and Wet Chemistry

In some cases, especially when iridium is alloyed or embedded within refractory materials, fire assay followed by wet chemical analysis offers the most definitive identification.

Use Case: Metallurgical and refining samples

Benefit: Trusted for commercial-grade accuracy in precious metals

Ledoux Insight: Our fire assay services are conducted in compliance with international standards and often used for iridium-bearing alloys and concentrates.

Density and Magnetism Tests

While less precise, simple physical tests can assist in field screening. Iridium’s extremely high density can be measured using water displacement methods. Non-magnetic behavior can help rule out iron-containing metals.

These tests are best used as preliminary tools before sending materials for certified lab testing.

Comparative Analysis

Iridium is often misidentified as platinum due to their similar appearance. Comparative spectral analysis can distinguish between them by isolating unique emission lines.

Ledoux Insight: We routinely compare PGMs within complex scrap to ensure our clients receive correct valuation for each metal.

Identifying iridium accurately is critical, not only for recovery value but also for regulatory reporting, alloy classification, and resale integrity. At Ledoux & Co., our full-service lab combines traditional methods with cutting-edge technology to deliver fast, traceable, and dependable results.

Iridium vs Platinum: How to Tell the Difference

Iridium and platinum are often mistaken for one another due to their visual similarity, shared use cases, and overlapping density ranges. However, the differences between the two metals are critical, especially when determining value or verifying alloy composition.

Density and Weight

Iridium: ~22.56 g/cm³

Platinum: ~21.45 g/cm³

While both are extremely dense, iridium is measurably heavier in identical volumes. Precision density testing can help differentiate the two.

Color and Finish

Iridium: Silvery-white with high reflectivity, resists tarnish entirely

Platinum: Slightly grayer tone, may dull slightly over time

Under magnification, iridium alloys often appear brighter and less worn than platinum after prolonged use, especially in jewelry and electrical components.

Hardness

Iridium is significantly harder than platinum, making it more brittle in pure form. Alloys containing iridium show greater scratch resistance and tool wear longevity than those with platinum.

Melting Point

Iridium: 2,446°C (4,435°F)

Platinum: 1,768°C (3,214°F)

This difference becomes especially relevant in high-temperature industrial environments or refining operations.

Spectroscopic Fingerprinting

In laboratory settings, the fastest and most definitive way to distinguish iridium from platinum is through XRF or ICP analysis. Each metal exhibits distinct spectral signatures, allowing labs like Ledoux & Co. to determine their presence, ratio, and purity with full ISO 17025 traceability.

Iridium in Catalysts and Industrial Waste: Hidden Value

Though rare in general circulation, iridium is present in specialized industrial applications where extreme durability and chemical resistance are essential. One of the most overlooked sources of recoverable iridium is spent catalytic materials.

Iridium in Catalytic Converters

While platinum and palladium are the primary metals used in automotive catalytic converters, iridium can appear in:

- High-performance or fuel cell vehicles

- Advanced oxidation systems

- Custom industrial emission controls

Due to its resistance to heat and corrosion, iridium enhances catalytic longevity and performance in aggressive operating environments. However, its concentration is often low, making detection difficult without advanced analysis.

Other Industrial Waste Sources

Iridium may also be present in:

- Used crucibles and laboratory equipment

- Spent chemical reactors

- Thin-film coatings in electronics and semiconductors

- Electroplating residues or process sludges

These materials may not show obvious signs of iridium content, especially when oxidized or alloyed. Standard visual inspection won’t suffice.

Why Testing Matters

Even trace amounts of iridium in industrial waste can represent substantial value when properly identified and recovered. But due to its scarcity and high melting point, recovery operations require precision testing, typically through ICP or fire assay.

Ledoux & Co. specializes in this type of analytical work, helping clients detect and quantify iridium in complex waste streams. Our ISO 17025-accredited methods ensure results you can act on with confidence, whether for refining, valuation, or compliance.

Why Lab Testing Is Essential for Iridium Identification

Identifying iridium visually or through field tests can offer preliminary clues, but these methods are not sufficient when accuracy, value, and compliance are on the line.

Visual Misidentification Is Common

Iridium shares physical traits with platinum, palladium, and rhodium. In alloyed or oxidized form, even experienced professionals can mistake one for the other. This can lead to:

- Underestimated material value

- Incorrect metallurgical classification

- Missed recovery opportunities

Trace Quantities Require Precision

In catalytic materials and industrial residues, iridium often appears in low concentrations. Detecting these trace amounts demands:

- ICP-MS or ICP-OES

- Fire assay with gravimetric finish

- High-purity standards and strict protocols

Ledoux & Co.’s laboratory is ISO 17025-accredited, meaning every result meets global standards for technical competence and method validation.

Testing Enables Actionable Decisions

Whether you’re trading PGMs, recycling electronic scrap, or managing refinery inputs, accurate iridium identification supports:

- Fair market pricing

- Regulatory compliance

- Confident downstream processing

When the margin of error affects profitability or operational trust, relying on professional analysis isn’t optional, it’s essential. Ledoux & Co. provides that assurance, backed by more than 140 years of metallurgical expertise.

Final Words: Unlocking Iridium’s Value with Trusted Testing

Knowing how to identify iridium, whether in scrap metal, jewelry, or industrial waste, is more than a technical skill. It’s a direct pathway to maximizing value, reducing risk, and maintaining accuracy in high-value material transactions.

While visual inspection and field tests provide initial clues, only laboratory testing can confirm iridium’s presence with certainty. This is especially true in alloys, catalysts, and electronic components where iridium is present in low or complex concentrations.

At Ledoux & Co., we offer ISO 17025-accredited metallurgical testing services designed for precision and reliability. Our advanced methods, from XRF and ICP to fire assay, help clients recover iridium confidently and comply with the highest industry standards.

Whether you’re managing recycled materials, validating high-purity content, or refining precious metals, trust Ledoux to deliver certified results that protect your investment and reputation.

Submit Your Iridium Sample for Certified Testing

Think you’ve found iridium in your scrap, jewelry, or industrial material? Get confirmation with ISO 17025-accredited testing from Ledoux & Co.

- Trusted for 140+ years

- Precise results using XRF, ICP, and fire assay

- Fast turnaround, confidential reports

Contact Us to discuss your testing needs.