Copper wire recycling is a profitable and sustainable business opportunity that transforms waste into measurable value.

In this article, we explore the science, process, and profitability of copper wire recycling, from stripping and sorting to purity testing, selling, and validating with Ledoux & Co.

What Is Copper Wire Recycling?

Copper wire recycling encompasses the systematic recovery and repurposing of copper from discarded wiring, offering both environmental and economic benefits.

Definition & Scope

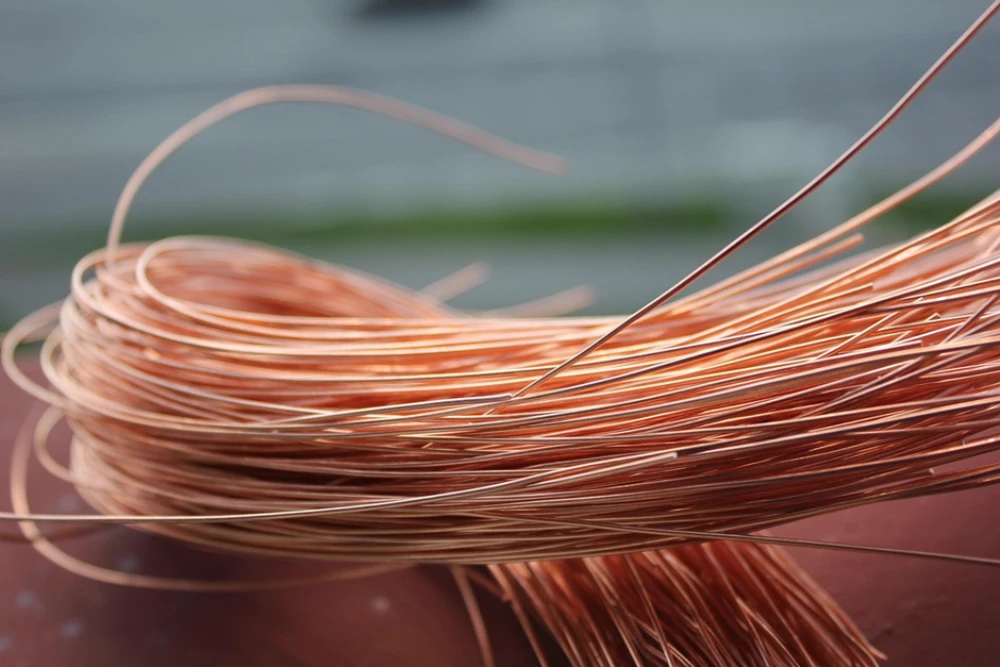

Copper wire recycling is the acquisition and processing of multiple copper wire forms, bare bright, insulated, industrial cable, or bus bar wire, into high-value copper ready for reuse.

Photo: Unsplash

It is distinct from other copper recovery processes involving printed circuit boards (PCBs) or copper alloys used in bus bars, as it primarily targets electrical, power, and communication cabling.

At Ledoux & Co., we view copper recycling as both a technical process and a validation-driven discipline, where assay accuracy directly influences market value.

Types / Grades of Copper Wire

Grading copper wire by purity and condition determines its market value, with higher grades fetching premium prices:

- Bare Bright Copper: Uncoated, oxidation-free, and clean. This grade yields the highest resale value due to its purity, often exceeding 99.9% copper content.

- #1 Copper Wire: Slightly oxidized copper with minor surface imperfections but minimal attachments.

- #2 / Mixed / Insulated Wire: Includes coated, enamel-insulated, or communication-grade wire requiring further stripping or cleaning.

- Tin-Plated, Nickel-Plated, and Enamel-Coated Variants: Contain secondary coatings or plating layers, necessitating additional chemical or mechanical treatment for purity recovery.

Why Copper Wire Recycling Matters for Business

Understanding the financial, operational, and strategic aspects of copper wire recycling helps businesses optimize returns and minimize risks.

Revenue Potential & Margins

Different copper grades command different prices. Bare bright copper yields the highest margins, while insulated or contaminated wire fetches less.

Photo: Pixabay

By stripping and cleaning wire, recyclers can increase profits by $12–$21 per 100 pounds for certain gauges. Clean, sorted copper wire consistently outperforms mixed scrap in resale markets.

Cost & Risk Considerations

Running a copper wire recycling operation involves equipment, labor, and compliance costs. Contamination, theft, and misgrading pose financial risks.

Moreover, illegal insulation burning releases toxic fumes and violates environmental regulations, making safe stripping methods essential.

Strategic & Competitive Importance

In competitive recycling markets, trust and traceability are key differentiators. Businesses that can validate copper content through reliable testing enjoy fewer disputes and stronger relationships. Ledoux & Co.’s ISO 17025-accredited assays add measurable credibility to every transaction.

Methods & Processes in Copper Wire Recycling

Effective copper wire recycling combines technical precision with operational efficiency. Below, we detail each major stage of the process.

1. Collection & Pre-Sorting

Copper wires are sourced from demolition sites, decommissioned equipment, and e-waste streams.

During initial sorting, wires are grouped by gauge, insulation type, and bundle configuration. Safety measures, such as de-energizing and inspection, protect workers and ensure reliable feedstock.

2. Insulation Removal / Stripping

Removing insulation is one of the most crucial and value-adding steps in copper wire recycling.

- Manual Stripping: Performed with knives or handheld tools, suitable for small batches. Though labor-intensive, it offers precise control for high-value wires.

- Mechanical Stripping: Uses automated rollers or rotating blades to process large volumes with minimal manual input. These systems enhance safety and consistency.

- Chemical / Thermal Stripping: While effective for complex wires, these methods are less common due to environmental hazards and regulatory limitations.

Efficient stripping increases copper yield. However, burning insulation is strictly prohibited for both safety and regulatory reasons.

3. Sorting & Classification

After stripping, copper is categorized by grade (bare, tinned, insulated, alloyed). Visual inspections or microscopy help detect impurities.

Removing foreign metals such as steel or aluminum ensures accurate grading. Documentation of batch weight, source, and date supports traceability.

4. Testing & Purity Validation

Representative sampling requires homogenizing lots via grinding or riffling to 30–100 grams, ensuring statistical reliability.

Techniques include inductively coupled plasma (ICP) spectroscopy for trace elements, X-ray fluorescence (XRF) for rapid screening, wet chemistry for precision, and fire assay for impurities.

At Ledoux & Co., our ISO 17025-accredited laboratory specializes in commercial-grade assays that meet financial transaction and dispute resolution requirements.

We maintain stringent QA/QC systems, perform inter-laboratory comparisons, and participate in global proficiency tests. These measures ensure our clients receive verifiable, reproducible data that buyers can trust.

Step-by-Step Guide & Tips (for Maximum Profit)

Copper wire recycling profitability depends on strategic planning, precision, and documentation.

Step 1: Audit & Plan Your Feedstock

Start by surveying your supply sources, expected volumes, and wire compositions. Estimate your break-even point by comparing stripping costs with projected resale value.

Step 2: Equipment & Tooling Decisions

Choose between manual and mechanical strippers based on scale and capital availability. Consider cost amortization, maintenance cycles, and safety systems.

Step 3: Efficient Stripping Strategies

Prioritize thicker wires for higher recovery. Batch similar wire types to reduce setup times. Track throughput and monitor yield losses to fine-tune efficiency.

Step 4: Quality Control & Sampling Process

Adopt standardized sampling, typically 30–100 grams per batch, and homogenize before analysis. Use duplicate and blank tests to validate consistency.

Pro Tips & Common Pitfalls

Here are some tips to help you optimize your copper wire recycling process:

- Avoid labor-intensive stripping of thin wires with low yield.

- Track shrinkage and weight loss throughout processing.

- Never burn insulation; use compliant methods only.

- Keep records for audits and re-evaluate yields periodically.

Related articles:

- Copper Method of Extraction: From Ore to Pure Copper: A detailed breakdown of how copper is mined, concentrated, smelted and refined into usable metal.

- How to Test Pure Copper: Top 6 Accurate Methods to Verify Purity: An overview of practical and laboratory methods for verifying the purity of copper metal.

- What Is Copper Ore Used For? Top 10+ Applications Explained: A review of the many industrial and everyday uses of copper derived from ore.

Why Partner with Ledoux & Co. for Copper Wire Recycling

Ledoux & Co. provides unparalleled analytical expertise and trusted validation services that empower recyclers and buyers alike. Our reputation is built on over a century of metallurgical precision.

Our Credentials & Expertise

Founded in 1880, we bring over 140 years as a premier metallurgical testing laboratory, specializing in base metals like copper, electroznic scrap, and trace impurities.

Photo: Pixabay

Our ISO 17025 accreditation and ISO 9001:2015 certification affirm technical competence, delivering consistent, unbiased assays for concentrates and scrap.

Commercial-Grade Assays & Validation

Our assays are legally defensible and suitable for financial transactions. We participate in international proficiency programs to uphold inter-lab reliability.

With strict QA/QC controls and full traceability, clients trust our data for high-stakes decisions.

On-Site Representation & Sampling

Ledoux & Co. offers on-site weighing, witnessing, and sampling. Our field representatives ensure accuracy, reduce shrinkage, and mitigate risk. This hands-on service enhances accountability during collection and processing.

Why Working With Us Adds Value

By partnering with us, recyclers gain market credibility and can command premium prices.

Our independent validation reduces audit exposure, accelerates transactions, and strengthens buyer-seller relationships. Many industry contracts and procurement programs require accredited testing, and we deliver it.

Submit a test sample today for our ISO 17025 commercial-grade assay, or engage on-site services to streamline your copper wire recycling operations.