Catalysts are vital in refining, chemical production, and automotive industries because they speed up reactions and improve efficiency. But catalysts do not last forever. Over time, they lose activity through heat, impurities, or wear. When this happens, they become spent catalysts.

Understanding the spent catalyst meaning is important for anyone working with metals, fuels, or recycling. These materials still contain valuable metals like platinum, palladium, and rhodium. How industries handle them affects costs, compliance, and sustainability.

As global focus shifts to resource recovery and environmental responsibility, knowing what spent catalysts are, and why they matter, has become essential.

What Is a Spent Catalyst?

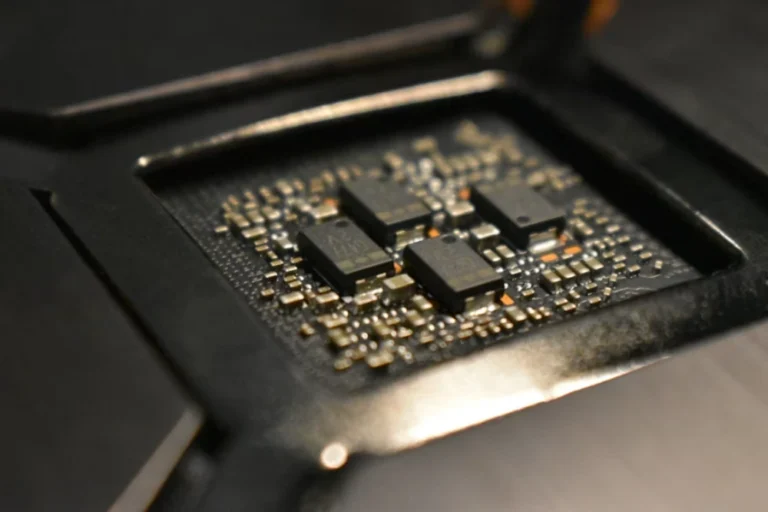

A catalyst speeds up chemical reactions without being consumed, but over time it loses activity. When this happens, it becomes a spent catalyst, meaning it can no longer perform effectively.

These catalysts are common in oil refineries, vehicles, and chemical plants. While “spent,” they still contain valuable metals such as platinum, palladium, or nickel. This makes them important resources for recovery and recycling rather than simple waste.

Why Spent Catalysts Matter in Industry

Spent catalysts may no longer drive reactions, but they hold significant economic and environmental value. Many contain platinum group metals (PGMs) that can be recovered and reused, reducing the need for new mining. Proper handling also prevents hazardous waste from entering landfills, helping industries meet environmental regulations.

For businesses, effective management of spent catalysts means lowering costs, ensuring compliance, and supporting sustainability goals. What might seem like industrial waste is actually a valuable resource when tested, recycled, and recovered responsibly.

Spent Catalyst Disposal and Recycling

Handling spent catalysts correctly is critical. Simply discarding them can release hazardous compounds and waste valuable metals. Traditional disposal, such as landfilling, is costly and harmful to the environment.

Recycling offers a better path. Through specialized processes, industries can recover precious and base metals like platinum, palladium, and nickel. These recovered materials are reintroduced into manufacturing, reducing dependence on new mining and lowering costs.

Accurate testing is the first step. By analyzing metal content, companies know whether recycling is economically worthwhile and how to manage the material safely. This shift from disposal to recycling turns spent catalysts into a resource rather than a liability, aligning industries with both sustainability and profitability.

Precious Metal Recovery and Value

Many spent catalysts contain platinum group metals such as platinum, palladium, and rhodium. These are highly valuable due to their rarity and their role in refining and emissions control. Recovering them from spent catalysts not only reduces costs for industries but also lessens reliance on mining, which is energy-intensive and environmentally taxing.

The value of recovery depends on accurate testing. Determining the exact content of PGMs ensures fair valuation and guides recycling decisions. For businesses, this process turns spent catalysts into revenue streams while supporting global sustainability goals. In today’s markets, where precious metals command high prices, recovery makes spent catalysts too valuable to ignore.

How Ledoux & Co. Supports Industries

Recovering value from spent catalysts starts with precise testing. That is where Ledoux & Co. stands out. With over 140 years of experience and ISO 17025 accreditation, the laboratory delivers accurate, unbiased results that industries can trust.

From catalyst testing and precious metal analysis to on-site representation, Ledoux helps businesses make informed decisions about recycling and recovery. By combining scientific rigor with quick turnaround times, the team ensures clients minimize risk, stay compliant, and maximize value.

Businesses can submit a sample today to see the true potential hidden in their spent catalysts.

Final Words

The spent catalyst meaning goes far beyond a simple definition. These materials, once inactive, remain valuable resources for industry. By focusing on proper testing, recycling, and recovery, businesses can reduce costs, stay compliant, and support sustainability. Partnering with experts like Ledoux & Co. ensures every spent catalyst is managed with accuracy and confidence.