Auto catalyst recycling is the process of recovering precious metals from spent automotive catalysts, most commonly found in catalytic converters. These components contain high-value materials like platinum, palladium, and rhodium, making them a valuable source of revenue when properly recycled.

For businesses that handle scrap, refining, or materials processing, understanding how this recycling works is critical to maximizing returns and staying compliant. But to extract full value, accuracy matters. From sampling to metal valuation, each step plays a role in determining how much your scrap is really worth and how much profit you’re leaving on the table.

What Is Auto Catalyst Recycling?

Auto catalyst recycling refers to the recovery of precious metals from spent catalytic converters. These devices, found in nearly every gasoline or diesel vehicle, use ceramic or metallic cores coated with platinum group metals (PGMs), primarily platinum, palladium, and rhodium, to reduce harmful emissions.

Once a vehicle reaches end-of-life or the converter is replaced, these components become valuable scrap. Rather than discard them, businesses can recycle catalytic converters to recover these rare metals for reuse in manufacturing, electronics, and new automotive catalysts.

The process is more than just collecting and melting down scrap. The materials must be carefully extracted, crushed, homogenized, and tested to determine their exact metal content. This is what makes catalytic converter recycling so specialized and potentially lucrative.

Because PGM prices are volatile and often quite high, even a small error in metal content estimation can lead to significant financial loss. That’s why businesses engaged in recycling must understand both the science and economics of recovery, especially if they’re processing high volumes of converters.

The Auto Catalyst Recycling Process Explained

While catalytic converters may look like simple car parts, recovering value from them is a technical, multi-stage process. Effective auto catalyst recycling requires precision at every step, from collection to final valuation. Here’s how the process works for businesses.

1. Collection & De-Canning

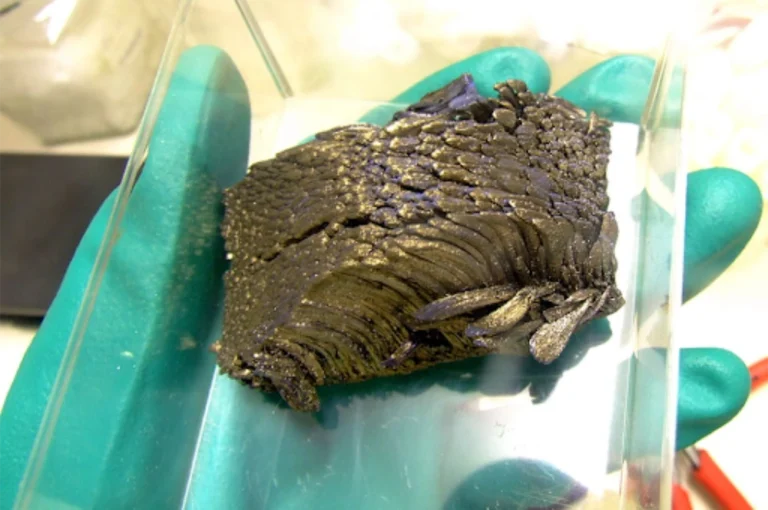

Used converters are collected from auto recyclers, repair shops, or scrapping operations. The outer shell is cut open (a process called de-canning) to access the monolith, the ceramic or metallic core containing the platinum group metals.

2. Crushing & Homogenization

The monolith is ground into fine powder to create a uniform sample. Homogenization is essential. Inconsistent sampling can result in inaccurate readings and unfair payouts during refining.

3. Sampling & Analysis

A small portion of the powdered catalyst is sent for laboratory testing. At this stage, the accuracy of analysis becomes critical. Labs use methods like ICP, fire assay, or X-ray fluorescence (XRF) to determine exact metal content.

4. ISO 17025 Catalyst Testing

Businesses that rely on catalyst results for financial transactions should only work with ISO 17025-accredited labs. This international standard guarantees technical competence, traceability, and standardized procedures, protecting you from costly errors or disputes.

5. Final Valuation & Refining

Based on the lab’s results and current PGM market prices, recyclers or refiners assign a value to the material. Only after this valuation is the material processed and refined for reuse.

Each phase is a potential risk or reward. The difference is almost always in the quality of testing.

The Profit Potential: How to Maximize Scrap Value

The value of a spent catalyst can range from a few dollars to thousands, depending entirely on its metal content and how accurately it’s assessed. That’s why businesses in the recycling chain must understand what impacts precious metal scrap valuation and how to avoid common pitfalls.

What Determines Value?

- Metal composition. Catalysts with higher platinum, palladium, or rhodium content are worth significantly more.

- Purity and uniformity. Poor sampling or mixed batches can distort results.

- Market pricing. PGM values fluctuate daily, so timing plays a role too.

Where Businesses Lose Profit

Many recyclers rely on generic grading systems or estimations instead of precise analysis. This can lead to underpayments, disputes, or missed financial opportunities. In bulk operations, even a small deviation such as a 0.5% error in rhodium estimation can translate to thousands in lost revenue.

How to Maximize Return

- Always homogenize batches before sampling.

- Work with independent, accredited labs, not buyers who test in-house.

- Request detailed assay reports, not just payout numbers.

When the payout is based on trace elements measured in parts per million, there is no room for guesswork. Accurate testing is your strongest asset in auto catalyst recycling and your biggest profit lever.

This may be relevant to you:

- Explore Why ISO 17025 Is Important For Lab Accuracy and Trust

- What Are PGMs? Key Properties, Applications, and Market Value

Choosing the Right Partner for Auto Catalyst Recycling

Recycling spent automotive catalysts is only as effective as the partner you choose to handle the analysis. Without the right lab, businesses risk inaccurate valuations, delayed payments, and regulatory setbacks, all of which affect your bottom line.

When selecting a catalyst recycling partner or assay lab, look for:

- ISO 17025 accreditation for proven testing accuracy

- Experience with auto catalyst materials and PGM analysis

- Independence and transparency (not tied to refiner payouts)

- Clear documentation and fast turnaround

Ledoux & Co. stands out as a leader in this space, offering ISO-certified catalyst testing services backed by over a century of metallurgical expertise. Their labs are equipped for high-volume, high-precision analysis using fire assay, wet chemistry, and advanced instrumental methods. Whether you are submitting samples for one-time valuation or ongoing refining, Ledoux ensures that your results are both accurate and commercially defensible.

Looking to streamline your process and reduce financial risk? Start with a trusted testing partner.

Final Takeaways

Auto catalyst recycling is more than a sustainability measure. It is a revenue opportunity that rewards precision. From understanding the process to choosing the right lab, every step affects your profit margin.

Whether you are a recycler, smelter, or manufacturer, working with an accredited, independent lab ensures you get the most from your spent catalysts.

Ledoux & Co. delivers certified, commercial-grade analysis backed by over 140 years of metallurgical expertise.