The palladium catalytic converter has become increasingly important as global emission standards tighten and metal prices fluctuate.

In this guide, we explain what palladium does inside converters, how it works, how much it’s worth, and why accurate testing is crucial for recyclers and businesses.

What Is a Catalytic Converter and Why Does It Matter?

Before understanding palladium catalytic converter, it’s essential to know what catalytic converters are and why they’re central to both emission control and metal recovery industries.

What Is a Catalytic Converter?

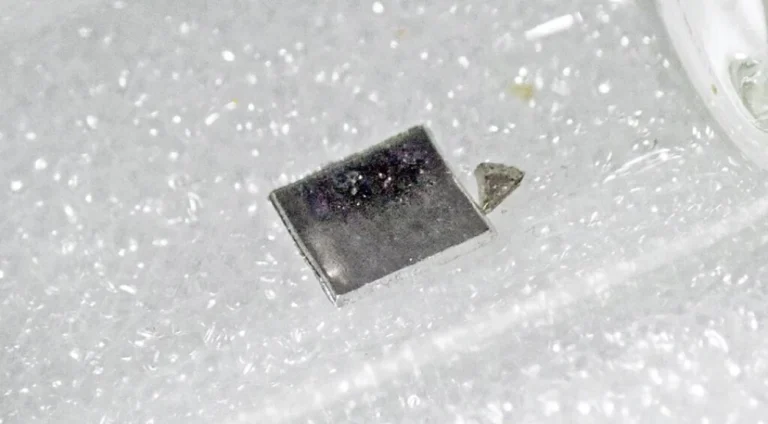

A catalytic converter is a key component of a vehicle’s exhaust system, designed to reduce harmful emissions. It contains a substrate, typically ceramic or metallic, coated with a washcoat that holds precious metal catalysts such as platinum, palladium, and rhodium.

Photo: Unsplash

These catalysts facilitate the “three-way” conversion process, transforming carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) into less harmful gases like carbon dioxide (CO₂), water vapor, and nitrogen. Modern converters can achieve conversion efficiencies as high as 98%, depending on temperature and design.

The Role of Palladium in Converters

Palladium (Pd) mainly oxidizes carbon monoxide and hydrocarbons, making it crucial in gasoline engines. Modern converters usually hold 2–7 grams of Pd, and demand has surged as emission standards tighten.

For recyclers, that small amount of metal means real value. Market swings make accurate testing essential for fair pricing and transparency.

Why It Matters to Recyclers, OEMs, and Regulators

For recyclers, palladium represents significant economic value. Market volatility directly impacts converter scrap prices, making precise analysis critical. Regulators and OEMs also rely on accurate measurement to ensure compliance and transparency.

Given the rise in converter theft and counterfeit materials, certified assays, like those provided by Ledoux & Co., are indispensable for ensuring trustworthy valuation and sustainable recycling practices.

What is the Value of Palladium?

Understanding the value of palladium requires insight into both market dynamics and the actual metal content within converters.

Palladium Market Price & Trends

As of the latest data, palladium trades around US$1,438 per ounce, though this price fluctuates due to geopolitical tensions, mining output, and shifts in automotive demand.

Over the past decade, prices have swung between $1,000 and over $3,000 per ounce, reflecting its rarity and essential role in emission control.

Metal Content Estimate & Conversion to Value

Theoretical value estimation begins with determining palladium content per converter. For instance, a unit with 5 grams of Pd translates to roughly $230 in metal value at current market rates.

However, recovery yields, refining losses, and processing costs must be factored in.

Photo: Wikimedia

Real-world scrap converter prices average around $98 per unit in the U.S., with some high-performance converters reaching several hundred dollars. Additional PGMs such as platinum and rhodium further enhance total converter value.

How Palladium Works (Chemistry & Mechanism)

To appreciate palladium’s catalytic role in palladium catalytic converter, we must examine its chemistry, structure, and operational limits.

Chemical Reactions & Catalysis Basics

Palladium acts as a surface catalyst that facilitates redox reactions. During oxidation, CO and hydrocarbons interact with oxygen on the Pd surface, forming CO₂ and H₂O.

Its effectiveness depends on surface area, temperature (typically 300–800°C), and resistance to deactivation from sulfur or lead contamination.

Catalyst Architecture & Distribution

Inside a converter, the substrate’s honeycomb structure maximizes surface contact. The washcoat, composed of alumina and other oxides, anchors Pd nanoparticles, each only a few nanometers wide.

These particles provide reactive sites for gas conversion. In multi-metal systems, palladium works synergistically with platinum and rhodium for enhanced durability and conversion efficiency.

Limitations, Degradation & Optimization

Over time, converters degrade due to thermal sintering, poisoning, or physical wear. Research continues into reducing Pd loading while maintaining efficiency, using alloyed catalysts and optimized support materials. Recycling and regeneration also pose challenges due to variability in spent converter compositions.

How Palladium Impacts the Value of Recycled Converters

For recyclers and refiners, the concentration and recoverability of palladium directly dictate the commercial value of a spent converter.

From Spent Converter to PGM Recovery

The recycling chain includes core acquisition, decanning, pre-processing, sample homogenization, and metallurgical recovery. Each step introduces potential losses or assay errors. Accurate sampling, representing the full batch, is essential to fair payout determination.

Value Attribution & Pricing Mechanisms

Buyers price converters based on their known model codes, which correlate to historical assay data. Premiums apply to converters with high PGM loadings.

Photo: Wikimedia

Conversely, unknown or contaminated units are discounted. Certified assay data from Ledoux & Co. enables recyclers to negotiate confidently and ensure transparent valuation.

Risk, Fraud & Quality Assurance

Mislabeling, sampling bias, and adulteration are ongoing risks in the converter trade. Ledoux & Co. mitigates these risks through ISO 17025 accreditation, strict chain-of-custody protocols, and decades of expertise. Our traceable and certified assays protect recyclers against underpayment and ensure full regulatory compliance.

Testing for Palladium in Catalytic Converters

Different methods offer trade-offs in speed, cost, and precision.

Sample Preparation & Homogenization

Accurate results start with proper preparation. The converter core is decanned, and the substrate is ground to a fine powder (typically 70 mesh). Samples of 30–100 g are homogenized to ensure representativeness before testing.

Analytical Methods (Pros / Cons)

Common analytical techniques include:

- XRF (X-Ray Fluorescence): Fast and non-destructive, but limited by surface analysis depth.

- ICP-OES / ICP-MS: Offers high precision through wet digestion and solution analysis.

- Fire Assay / Cupellation: Gold-standard method for trace metal quantification.

- Instrumental Neutron Activation: Used for research-grade elemental validation.

Accuracy, Uncertainty & Traceability

Error sources include sample heterogeneity and matrix effects. Certified labs use reference standards, replicate runs, and blanks to minimize uncertainty. ISO 17025 accreditation ensures results are traceable and defensible for commercial use.

Speed, Cost & Turnaround

While high-precision methods take longer, Ledoux & Co. optimizes both efficiency and reliability. Our team balances speed with analytical depth, delivering dependable results without compromising accuracy.

Interpreting Results for Value Estimation

Test results typically report Pd content in mg/kg or ppm. These figures are converted into grams per converter and multiplied by current spot prices to estimate metal value. Our comprehensive assay reports combine all PGMs and offer recyclers an authoritative basis for pricing negotiations.

Why Partner with Ledoux for Testing

Ledoux & Co. brings over a century of analytical excellence to catalyst and converter testing. As an ISO 17025 and ISO 9001:2015 accredited laboratory, we offer independent, verifiable results trusted across the recycling and refining industries.

Our palladium catalytic converter assays help clients secure better recycling contracts, validate supply chains, and ensure regulatory compliance. We invite recyclers, OEMs, and businesses to contact us for a quote or request a sample submission kit today.