In industries where every gram holds measurable value, PGM analysis is more than just a technical procedure. It is a critical checkpoint for accuracy, profit, and trust. Manufacturers and recyclers alike rely on the precise measurement of platinum group metals like platinum, palladium, and rhodium to guide production, determine value, and meet regulatory standards.

Whether assessing spent catalysts, refining electronic scrap, or verifying material quality before resale, reliable testing plays a pivotal role in financial outcomes. A small miscalculation in purity or content can lead to costly errors or missed opportunities.

As global demand for PGMs increases, so does the need for testing that is not only fast, but scientifically exact. This guide explores what PGM analysis is, why it matters for your operation, and what to look for in a laboratory partner that delivers results you can act on with confidence.

What Is PGM Analysis? An Overview

PGM analysis refers to the scientific testing of platinum group metals, primarily platinum (Pt), palladium (Pd), and rhodium (Rh), but sometimes also including iridium, ruthenium, and osmium. These rare, high-value elements are widely used in industrial applications such as catalytic converters, electronics, chemical manufacturing, and jewelry. Because of their high market value and critical function, accurate analysis is essential for both commercial and regulatory purposes.

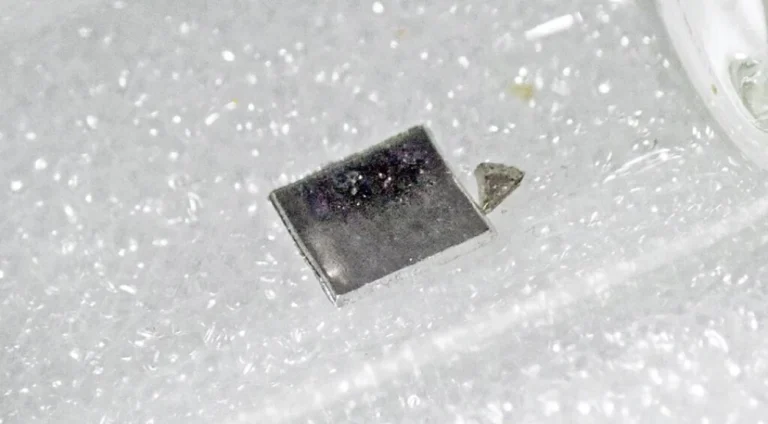

At its core, PGM analysis determines the precise composition and purity of a material sample. This might involve testing spent automotive catalysts, refining residues, electronic scrap, or mined concentrates.

Depending on the material’s form and intended use, analysts apply various techniques such as fire assay, wet chemistry, or advanced instrumental methods like ICP-OES or XRF to measure the exact percentages of each metal present.

The results from this analysis are used to validate material quality, guide purchase or sale transactions, and ensure that recycling and manufacturing operations remain economically and environmentally sustainable.

Why Recyclers Need PGM Analysis

- Maximizes profitability: Accurate testing ensures full recovery of platinum, palladium, and rhodium from spent catalysts, e-scrap, and industrial residues.

- Reveals true material value: Complex waste streams make it impossible to estimate PGM content accurately without professional analysis.

- Prevents financial loss: Guesswork can lead to undervalued deals or missed revenue opportunities.

- Supports fair negotiations: Certified data strengthens pricing discussions and reduces disputes, especially in international transactions.

- Handles market volatility: Timely, repeatable, and precise analysis protects profits as metal prices fluctuate.

- Detects trace levels: Advanced labs identify even small amounts of PGMs in ceramic honeycombs, metallic substrates, and circuit boards.

- Improves supply chain transparency: Detailed assays keep all stakeholders accountable from start to finish.

Why Manufacturers Depend on PGM Testing

- Ensures product quality & precision

- Platinum, palladium, and rhodium are critical in automotive catalysts, electronics, and other high-performance parts.

- Testing confirms metal content meets technical and contractual standards.

- Prevents costly issues

- Verifies raw materials before use and analyzes used catalysts for recovery.

- Reduces risk of underperforming products, failed inspections, or wasted inventory.

- Supports regulatory compliance

- Provides documentation required for emissions control, electronics manufacturing, and international trade.

- Helps meet environmental and industry reporting standards.

- Improves process control & reduces risk

- Reliable lab results give manufacturers confidence in quality and costs.

- Eliminates guesswork—protecting margins and operational integrity.

PGM Testing Methods: Lab Techniques That Matter

Testing for platinum group metals relies on a range of scientific methods, each suited to different materials and levels of precision.

The most commonly used techniques include:

- Fire Assay A high-temperature fusion process used to extract precious metals from solid materials like catalysts or refining residues. It is known for accuracy but requires experienced handling.

- ICP-OES (Inductively Coupled Plasma Optical Emission Spectrometry) A laboratory technique that measures trace elements in dissolved samples. It is effective for both solids and liquids and provides detailed multi-element data.

- XRF (X-ray Fluorescence) A rapid, non-destructive method used to screen materials and estimate metal content. While not as precise as chemical analysis, it is useful for quick assessments.

The right method depends on the form of the material, the concentration of metals, and the purpose of the analysis. In some cases, multiple techniques are used in combination to confirm results or validate findings.

Choosing the Right Testing Lab

For both recyclers and manufacturers, the lab you choose must be equipped to handle complex materials, deliver repeatable results, and support your operational goals.

Key factors to consider when selecting a testing partner:

- Proven experience with PGM-containing materials like spent catalysts, e-scrap, and metal concentrates

- Access to advanced techniques such as fire assay, ICP, and wet chemistry

- Transparent sample handling and clear documentation

- Fast turnaround without sacrificing quality

- Certification and adherence to global testing standards

Accurate PGM Analysis Is the Key to Value and Compliance

Whether you are refining spent materials, managing manufacturing inputs, or preparing for high-stakes transactions, PGM analysis is the tool that protects your margins and reputation.

With platinum group metals trading at high market values and regulatory expectations rising, there is no room for guesswork. Accurate, well-documented testing helps you recover more, waste less, and operate with confidence in a competitive industry.

At Ledoux & Co., we provide the precision, speed, and integrity needed to support your business. Our testing services are built on scientific rigor and over 140 years of industry trust.

Need expert PGM analysis? Submit your sample or contact our team to get started today.