Rare earth elements (REEs) are essential to modern manufacturing, clean energy, electronics, and advanced alloys. While mining attracts attention, rare earth element processing and separation define whether a project succeeds commercially.

Metallurgical testing, accurate analysis, and scalable separation data ultimately determine technical feasibility and long-term economic viability.

Processing Challenges in Rare Earth Element Projects

Rare earth element processing presents a unique combination of mineralogical, chemical, and regulatory challenges.

Ore Variability and Mineralogy Drive Processing Complexity

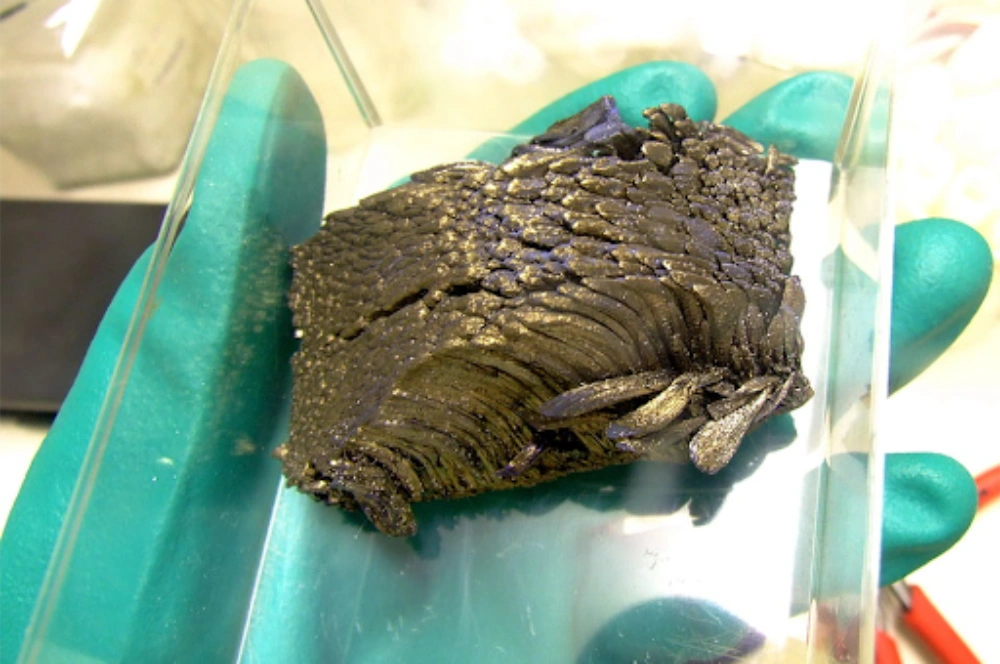

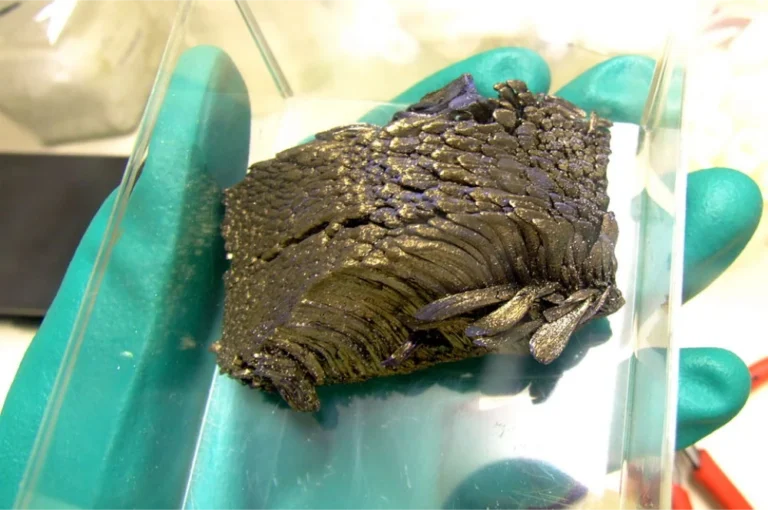

Rare earth elements do not occur as native metals but are hosted within complex mineral assemblages. Common REE-bearing minerals include bastnäsite (fluorocarbonates), monazite (phosphates), and xenotime (yttrium phosphates), each responding differently to crushing, grinding, leaching, and separation techniques.

Processing complexity increases due to variability in rare earth distribution between light and heavy REEs, the presence of gangue minerals such as iron oxides, silicates, and carbonates, and the frequent association with radioactive elements like thorium and uranium.

Without early-stage material characterization, projects risk designing flowsheets that fail under real operating conditions. Thorough mineralogical and chemical analysis at the outset reduces uncertainty and enables informed process design.

Chemical Similarities Make Separation Technically Difficult

REEs exhibit nearly identical ionic radii and chemical behavior, making selective separation exceptionally challenging. Achieving commercial-grade products often requires multi-stage separation circuits, typically involving hundreds of solvent extraction steps or complex ion exchange systems.

Minor inefficiencies at each stage can compound across large circuits, significantly reducing overall recovery and increasing operating costs. High analytical precision is essential to measure small concentration differences, validate separation efficiency, and confirm product purity throughout development and scale-up.

Environmental and Regulatory Constraints

Rare earth processing generates acid consumption, complex waste streams, and radioactive byproducts that must be carefully managed. Regulatory requirements vary by jurisdiction and directly influence flowsheet design, residue handling, and long-term liability.

Poorly designed processing routes increase compliance risk, permitting delays, and lifecycle costs. Integrating environmental considerations early in testwork supports sustainable operations and reduces the likelihood of regulatory setbacks.

Separation Technologies That Determine Project Viability

Rare earth element processing success ultimately depends on the ability to separate individual elements to marketable purities.

Solvent Extraction as the Industry Standard

Solvent extraction remains the dominant commercial method for rare earth separation. These circuits can involve hundreds or thousands of stages to achieve high-purity individual REEs, making them sensitive to feed chemistry, impurity levels, and reagent control.

Small variations in solution composition can disrupt separation performance, underscoring the importance of comprehensive laboratory testing. Controlled bench-scale experiments provide the data needed to design stable and efficient extraction circuits before scale-up.

Emerging and Alternative Separation Methods

Alternative technologies such as ion exchange, membrane separation, and molecular recognition systems continue to attract research and development interest. These approaches may reduce reagent consumption or environmental footprint, but most remain at early stages of commercialization.

Scalability, long-term stability, and consistency are key concerns for emerging methods. Independent validation through rigorous testing is necessary to confirm real-world applicability beyond controlled laboratory conditions. Without this verification, alternative technologies carry significant technical and financial risk.

Analytical Accuracy Enables Process Optimization

Accurate chemical analysis underpins every stage of rare earth separation. Trace impurities can significantly impact product value, downstream performance, and customer acceptance.

High-quality analytical data allows operators to optimize separation circuits, confirm product specifications, and support commercial contracts. Commercial-grade assays provide the confidence required for financing decisions, off-take agreements, and regulatory reporting.

Scaling Laboratory Results to Commercial Operations

Rare earth element processing data must be both technically sound and scalable to support real-world operations. Bridging the gap between laboratory testing and commercial plants requires disciplined methodology and independent validation.

Representative Sampling and Sample Preparation

Representative sampling is essential to ensure test results accurately reflect bulk material behavior. Heterogeneous REE distributions make improper sampling a common source of error in metallurgical testing.

Poor sample preparation can lead to misleading recovery, separation, and reagent consumption data. At Ledoux & Co., we emphasize correct sampling protocols and preparation techniques before analysis, ensuring that laboratory results provide a reliable foundation for process decisions.

Pilot-Scale Validation Reduces Financial Risk

Laboratory success does not guarantee commercial performance. Pilot-scale testing validates reagent consumption, mass balance, impurity behavior, and recovery under realistic operating conditions.

Early pilot validation identifies design weaknesses before capital is committed, preventing costly redesigns and schedule delays. This step is critical for investor confidence and project financing.

Independent Metallurgical Testing Builds Confidence

Third-party testing provides objectivity and credibility that internal data cannot match. ISO 17025–accredited laboratories deliver results suitable for regulatory submissions, partner reviews, and financial transactions.

Independent verification reduces disputes, strengthens due diligence, and supports transparent decision-making throughout project development.

How Ledoux & Co. Supports Rare Earth Element Processing Success

Rare earth element processing requires analytical precision, technical expertise, and independent validation. At Ledoux & Co., we support clients at every stage of processing and separation development.

Rare Earth Processing and Separation Testing Expertise

We provide comprehensive wet chemistry, ICP, and advanced instrumental analysis for rare earth elements. Our capabilities allow for accurate measurement of trace REEs, impurities, and associated elements that influence processing performance.

This data supports process design, optimization, troubleshooting, and quality control across exploration, development, and production stages.

Scaling Results Toward Commercial Operations

Our role extends beyond laboratory measurements. We help translate analytical data into actionable processing decisions that support scale-up and commercialization.

Independent verification from Ledoux & Co. strengthens investor confidence, supports partner evaluations, and reduces technical uncertainty. Our experience spans primary ores, concentrates, recycled materials, and processing residues.

Independence, Accuracy, and Industry Trust

Family-owned and unbiased since 1880, Ledoux & Co. operates with a long-standing commitment to accuracy and integrity. We are ISO 17025 accredited and ISO 9001:2015 certified, ensuring consistent quality and traceability.

Global manufacturers, refiners, and recyclers trust our results to support critical technical and commercial decisions.

Key Takeaways

Rare earth element processing and separation challenges, not mining, define rare earth project viability. Independent, ISO 17025–accredited analysis reduces technical and financial risk across development stages.

At Ledoux & Co., we help turn laboratory insights into commercial confidence. Partner with us to support your rare earth processing goals with accuracy and integrity.

FAQs

Rare earth element processing often raises practical and technical questions as projects move from concept to execution.

1. How do impurities affect rare earth product value?

Even trace impurities can reduce purity specifications, limiting marketability and increasing refining costs.

2. Are alternative separation technologies commercially proven?

Most alternatives are still under development and require independent validation before large-scale adoption.

3. Why is independent laboratory testing important?

Third-party testing ensures objectivity and builds confidence among investors, regulators, and partners.

4. How does ISO 17025 accreditation impact project acceptance?

Accreditation ensures analytical results meet international standards for accuracy and reliability.

5. Can analytical data support financing and off-take agreements?

Yes, high-quality analytical data underpins technical due diligence and commercial negotiations.