Facts about rare earth elements show that these materials are essential inputs for modern manufacturing, clean energy, and advanced technologies. Despite their importance, rare earth elements (REEs) are widely misunderstood because of their name, chemistry, and complex supply chains.

This article explains what REEs are, why they matter, where they are used, and why accurate ISO 17025 testing is critical.

What Are Rare Earth Elements? A Practical Overview for Industry

Understanding the facts about rare earth elements begins with clarifying what they are and why they present analytical and commercial challenges.

Definition And Classification Of Rare Earth Elements

Rare earth elements consist of 17 metallic elements: the 15 lanthanides (Lanthanum through Lutetium), plus Scandium and Yttrium.

These elements share very similar chemical behavior, which makes separation technically complex and costly. They typically occur together in ores rather than as isolated elements, increasing processing and analytical difficulty.

Why They’re Called “Rare” (And Why That’s Misleading) ?

Rare earth elements are not always geologically rare.

In fact, several REEs are more abundant in the Earth’s crust than copper, lead, or precious metals. The term “rare” instead reflects how infrequently they occur in concentrated, economically recoverable deposits.

REEs are seldom found in high-grade, single-element ores or in mineral forms that are easily processed. Complex mineralogy, high processing costs, and environmental and regulatory considerations all raise barriers to development.

These challenges make accurate analytical data essential for determining whether a material is commercially viable and suitable for long-term investment.

Rare Earth Element Properties That Drive Industrial Demand

Key facts about rare earth elements are rooted in their unique properties, which underpin modern industrial and clean-energy technologies. These characteristics explain why REEs are indispensable despite being used in small quantities.

Physical And Chemical Characteristics

Rare earth elements exhibit unique magnetic, optical, catalytic, and thermal properties.

- Neodymium and Dysprosium enable high-strength permanent magnets used in electric motors and generators.

- Europium and Terbium provide luminescent properties for displays and LEDs.

- Cerium and Lanthanum act as effective catalysts in petroleum refining and emissions control.

These characteristics explain why even small quantities of REEs deliver outsized industrial value.

Why Do Small Amounts Have Big Value ?

Rare earth elements are typically used in trace or minor concentrations, yet their impact on performance is significant.

A fraction of a percent can determine whether a magnet meets specification, a catalyst performs efficiently, or an alloy achieves the desired durability.

Small analytical errors can lead to mispriced material transactions, incorrect blending or refining decisions, and disputes between buyers and sellers. Commercial-grade analysis ensures reliable valuation, supports process optimization, and mitigates financial and operational risk across the supply chain.

Industrial Uses Of Rare Earth Elements

Understanding the real-world facts about rare earth elements requires examining how they are applied across industries. These uses highlight why consistent quality and independent verification are essential.

Core Industrial Applications

Permanent magnets are used in electric vehicles, wind turbines, robotics, and industrial motors. Catalysts support petroleum refining and automotive emissions control. Advanced materials include ceramics, glass polishing powders, and specialty coatings.

Metallurgical alloys benefit from improved strength, corrosion resistance, and temperature stability. Each application depends on tight quality specifications and verified elemental content.

Recycling & Secondary Supply Importance

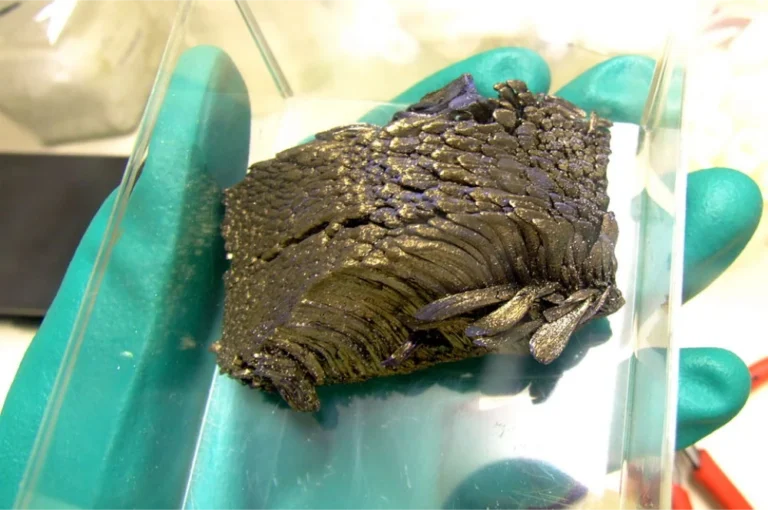

Recycling is becoming increasingly important for REE supply security. Secondary sources include spent catalysts, electronic scrap, and industrial residues.

Accurate analysis supports recovery efficiency, fair financial settlements, and sustainable sourcing. Independent laboratories help verify recoverable content and reduce uncertainty in recycling streams.

Why Accurate Rare Earth Element Analysis Matters ?

These facts about rare earth elements demonstrate why laboratory quality directly affects financial and operational outcomes.

Common Challenges In REE Analysis

Rare earth materials often contain multiple REEs in varying ratios along with interfering elements and complex matrices. Analytical challenges include incomplete digestion of refractory minerals, elemental overlap during measurement, and sample heterogeneity.

Screening methods such as X-ray fluorescence (XRF) alone are insufficient for commercial-grade results. They cannot reliably resolve low-level or overlapping REEs, making advanced techniques and rigorous quality control essential for dependable data.

Why Is ISO 17025 Accreditation Critical ?

ISO 17025 accreditation ensures that analytical laboratories operate with validated methods, documented quality control procedures, and traceability to NIST standards. Accredited results are suitable for financial transactions, contract settlements, and regulatory reporting.

For buyers and sellers, ISO 17025–accredited data reduces disputes and builds confidence in reported results. In markets where small concentration differences can carry large financial consequences, accreditation is not optional, it is essential.

How Ledoux Delivers Reliable Rare Earth Element Analysis

At Ledoux & Co., we provide analytical services designed to meet the highest commercial and regulatory standards.

What We Analyze

We analyze several rare earth–bearing materials, including ores, concentrates, and intermediate products. Our scope also includes mixed rare earth materials requiring separation insight, as well as separated rare earth oxides (REOs), metals, and alloys.

In addition, we test industrial products, catalysts, spent materials, and residues from mining, refining, recycling, and manufacturing operations. This broad capability allows us to support clients across the entire REE value chain.

Our Analytical Approach

Our laboratories use ISO 17025–accredited ICP-OES and ICP-MS techniques paired with optimized digestion procedures to ensure complete dissolution of challenging matrices. We apply rigorous QA/QC protocols using NIST-traceable standards to ensure accuracy and reproducibility.

We also develop custom methods for unique matrices and specialized commercial requirements. Our independent, unbiased results are suitable for financial use and provide the clarity and confidence our clients require.

Key Takeaways

Rare earth elements present high value but significant analytical complexity, making reliable testing essential for commercial success. Inaccurate data increases financial, operational, and contractual risk across the supply chain.

At Ledoux & Co., we provide independent, commercial-grade rare earth element analysis to support informed decisions. Partner with us to ensure clarity, confidence, and accuracy in every result.

FAQs

The following facts about rare earth elements address common questions we receive from industry professionals. These answers provide additional context beyond the main discussion.

1. Are rare earth elements regulated differently than other metals?

Yes, REEs are often subject to stricter environmental and export controls due to their strategic importance and processing impacts. Regulations vary significantly by jurisdiction.

2. Can rare earth elements be substituted in industrial applications?

In some cases, partial substitution is possible, but performance often declines. Many applications rely on specific REEs for unique properties.

3. Are rare earth oxides easier to analyze than ores?

Generally, yes. Oxides are more chemically uniform, but accurate quantification still requires accredited methods and traceable standards.

4. What documentation should accompany REE analytical results?

Reports should include method details, accreditation status, QA/QC data, and traceability information to support financial and regulatory use.