Understanding what is gold alloy is necessary since composition directly influences color, hardness, melting point, and corrosion resistance. Accurate assay of gold alloy guarantees value, safety, and reliability in applications.

In this article, we define “what are the alloys of gold?”, examine its classifications, explore multiple assay techniques with technical detail, and explain why alloy composition matters to industry and consumers.

What Is Gold Alloy?

What is alloyed gold? To appreciate Gold alloy’s importance, we must first define them and understand how purity is measured and standardized globally.

Definition & Purpose

Is gold an alloy or element? A gold alloy is gold mixed with other metals to alter or enhance its properties.

While the purest form of gold (24 karat) is precious because it is rare and shines, it is also too soft for practical uses. Pure gold can bend, scratch, or wear down rapidly, making it unsuitable for jewelry and industrial purposes.

Alloying gold with metals like copper, silver, nickel, or palladium helps improve its strength, durability, and resistance to deformation. Alloying also alters the color of gold to white, rose, green or other colors.

Measurement of Purity & Standards

Gold purity is usually graded by the karat system. Pure gold is 24 karat (24K), while 22K contains approximately 91.7% gold, 18K holds 75%, and 14K contains about 58.3%. Alongside karats, fineness (parts per thousand) is also used: for example, 750 fine gold corresponds to 18K.

Standards are not merely descriptive but carry legal weight. Hallmarking laws vary by country, requiring disclosure of purity and composition. Mislabeling alloys can lead to regulatory consequences, disputes, or consumer mistrust.

You may find this relevant:

Main Types of Gold Alloy

Is gold alloy real gold ? Gold alloys differ by appearance and function so that manufacturers, investors, and consumers can make better choices.

By Color & Appearance

Some metals produce various colors when mixed with gold:

- Yellow gold: A blend of gold, silver, copper, and sometimes zinc; retains the traditional golden hue and is favored for its timeless, warm look.

- White gold: Typically alloyed with nickel, palladium, zinc, or silver; often rhodium-plated for brightness and durability. It provides a modern, platinum-like appearance at a lower cost.

- Rose, pink, or red gold: Produced by adding additional copper and possibly silver, to create color from pale pink to garnet red. Used in designs that replicate vintage fashions.

- Green gold: An uncommon gold-silver alloy, with occasional cadmium or zinc content, becoming a light green tone. Traditionally used in specialized artistic pieces.

By Use or Function

Gold alloys also differ in purpose and application:

- Jewelry and decorative objects: Demand not only visual beauty but also scratch resistance, ease of fabrication, and compatibility with settings for gemstones.

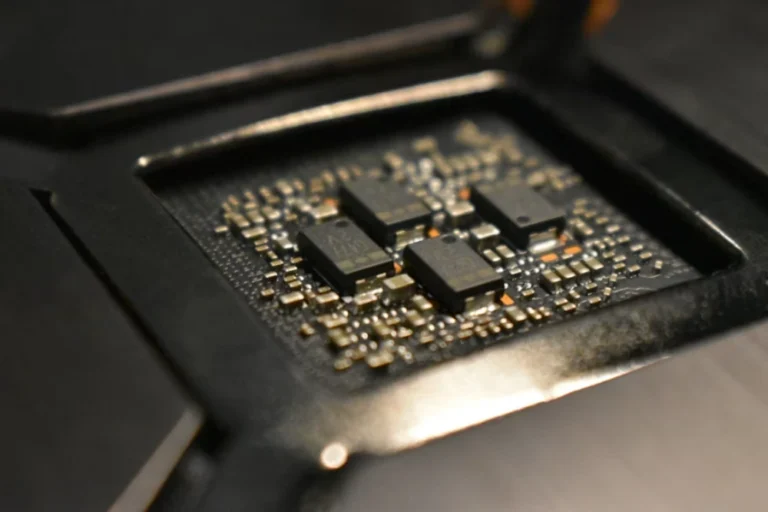

- Industrial uses: Gold alloys provide exceptional conductivity, resistance to corrosion, and reliability in connectors, contacts, and plating for high-performance circuits.

- Coins and bullion: Alloys balance durability and intrinsic value, preventing excessive wear while retaining investment-grade purity.

- Specialized alloys: Applied to aerospace, dentistry, and high-temperature engineering because of resistance to oxidation and mechanically stable performance under stress.

Methods to Assay Gold Alloy: Accuracy vs Practicality

Methods of assaying determine composition and purity. All methods are a balance between accuracy, speed, and convenience.

Fire Assay (Cupellation)

Fire assay is the oldest and most accurate technique. It is melting with flux, separation of base and precious metal by cupellation. It gives precise results which are even used as a world standard.

- Pros: Highly precise, world standard, most favored for bullion and refining.

- Cons: Destructive, time-consuming, needs sophisticated sample preparation and special laboratory equipment.

X-Ray Fluorescence (XRF)

XRF scans alloys through x-rays on the surface and measures emitted radiation.

- Pros: Portable, quick, non-destructive, minimal preparation, optimally suited to quick screening.

- Cons: Limited to surface composition; coatings or uneven layers may distort results, not suitable for high-value commercial.

Inductively Coupled Plasma Methods (ICP-OES / ICP-MS)

XRF analyzes alloys by directing x-rays at the surface and measuring emitted radiation. Modern handheld devices have expanded its accessibility, enabling on-site checks.

- Pros: Highly sensitive, detects multiple elements simultaneously, excellent for trace impurities and regulatory testing.

- Cons: Destructive, requires advanced laboratory setups and skilled operators, and may involve hazardous chemicals during preparation.

Other Methods (Acid Test, Electronic, Density)

Simpler methods include acid testing, electronic testers, and density/specific gravity measurements. These approaches have existed for centuries but remain in use for quick checks.

- Pros: Inexpensive, fast, accessible to jewelers and traders.

- Cons: Less accurate, sometimes destructive, dependent on operator expertise, and limited in detecting impurities or subtle differences.

Why Gold Alloy Matters

The composition of gold alloy has implications across economic, functional, and legal dimensions.

Value, Pricing & Investment

Purity directly influences value. Higher alloy content reduces intrinsic gold value. Trace impurities can diminish worth or lead to disputes during transactions, particularly in high-value bullion or jewelry sales.

Functionality & Durability

Alloying provides strength and hardness. For jewelry, this prevents scratches and deformation. For industrial uses, alloys offer corrosion resistance and thermal stability. Color stability and tarnish resistance depend heavily on alloy composition.

Regulatory, Legal, & Consumer Trust

Hallmarking regulations ensure accurate disclosure of purity. Misrepresentation can result in legal penalties and reputational damage. Industrial users rely on validated assay reports for compliance and performance assurance.

What Ledoux & Co. Offers for Gold Alloy Analysis

At Ledoux & Co., we provide comprehensive assay services to ensure accuracy, compliance, and confidence in gold alloy evaluation.

Our Assay & Analysis Capabilities

We perform fire assay, XRF, and ICP techniques, adapting to the needs of bullion dealers, jewelers, refiners, and manufacturers. Our lab handles a broad range of samples, including jewelry scrap, electronic components, high-purity bullion, and complex industrial alloys.

Quality, Accreditation & Accuracy

Ledoux & Co. maintains ISO 17025 accreditation for technical competence and ISO 9001:2015 certification for quality management. Our results meet the standards required for financial, regulatory, and contractual use, ensuring traceability and repeatability.

Client Benefits: Speed, Transparency, Support

We offer fast turnaround times, with methods selected based on sample type and desired accuracy. Clients receive transparent reports showing alloy composition, impurities, and detection limits. Our team also supports sample preparation, collection, and interpretation, reducing uncertainty in high-stakes environments.

Risk Mitigation, Trust & Compliance

Accurate assays reduce the risk of undervaluation, counterfeit materials, or regulatory non-compliance.

Our expertise ensures materials meet design and manufacturing requirements, particularly in jewelry and electronics. Clients trust us to verify supplier claims with precision, safeguarding investments and strengthening trust across supply chains.

Trust in Gold Alloy Quality with Ledoux & Co.

Understanding what is gold alloy is essential for accurate valuation, performance, and trust. At Ledoux & Co., we apply advanced methods such as fire assay, XRF, and ICP to provide results tailored to your needs.

Our ISO 17025 and ISO 9001:2015 certifications guarantee dependable, repeatable analysis. Contact us for gold alloy testing, quotes, or expert guidance to ensure your materials meet the highest standards.