Precious metals recovery refers to the process of extracting and quantifying valuable metals, particularly platinum-group metals (PGMs), from recycled, scrap, or spent materials. As industrial demand for PGMs grows, accurate recovery has become essential for maintaining profitability and resource efficiency.

At Ledoux & Co., we provide trusted precious metals recovery services backed by scientific rigor and precision. Our approach focuses on three core themes: preventing PGM loss, applying precise analytical methods, and ensuring maximum returns for our clients.

Why Professional Precious Metals Recovery Matters

Two key reasons reinforce the need for expertise: preventing avoidable losses and ensuring results that support confident business decisions.

The Risk Of Losing Value Without Proper Recovery

When precious metals, especially PGMs, are mismanaged, significant value can be lost throughout the recovery chain. Inefficiencies in sampling, handling, or analysis frequently lead to lower yields and inaccurate settlement values.

Photo: Vecteezy

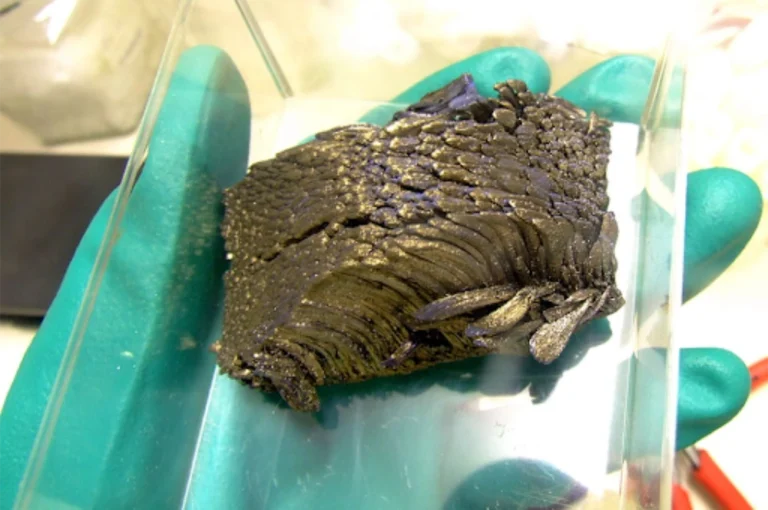

Scrap catalysts, electronic scrap, and spent industrial materials are particularly vulnerable to overlooked losses due to irregular metal distribution, improper preparation, or incomplete data. Even small errors in recovery can equate to thousands of dollars in unrealized revenue.

How Trusted Recovery Supports Business Goals

In this context, “trusted” means working with an accredited, independent, and scientifically rigorous laboratory. A trusted partner uses traceable methodologies, unbiased data reporting, and consistent controls, reducing financial, regulatory, and contractual risks.

Ledoux & Co. operates as a fully independent metallurgical laboratory, ISO 17025 accredited and ISO 9001:2015 certified. Our history of technical integrity provides clients with reliable results, risk reduction, and confidence that their materials are analyzed with absolute objectivity.

Understanding PGM Loss: Common Pitfalls and How We Avoid Them

Precious metals recovery becomes even more essential in processes where small errors can lead to substantial PGM losses.

Where Precious Metal Losses Typically Occur

In many facilities, value is lost long before a material reaches the laboratory.

Below are the most frequent causes:

- Sampling errors: Non-representative sampling, improper homogenization, or incorrect particle sizing result in biased data that misstates actual metal content.

- Weighing and handling issues: Spillage, contamination, and unsecured handling at the processing site contribute to avoidable physical losses.

- Inaccurate assay methods: Some operators rely solely on techniques like XRF, which are not suitable when high-accuracy PGM measurements are required.

- Poor documentation: Incomplete or inconsistent reporting obscures discrepancies and can lead to undervaluation during settlement.

Our Approach to Eliminate PGM Loss

Our role is to ensure every step of the process meets strict scientific standards that protect client value.

We do this through:

- On-site representation: We serve as your eyes and ears at the facility, monitoring sampling, weighing, and preparation.

- Strict sample preparation requirements: Materials must be homogeneous, properly ground (often 70-mesh), and provided in adequate mass (typically 30–100 g) for accurate analysis.

- Calibrated instrumentation: All analytical equipment is supported by NIST-traceable standards and rigorous ISO 17025 quality controls.

- Independent documentation: Our commercial-grade assay reports offer clear, unbiased, and audit-ready data.

Precise Analysis Methods at Ledoux

Our laboratory is built on method selection, capability, and accreditation that deliver consistently dependable results.

Choosing The Right Method For The Material

Different materials and metals require different analytical workflows. Accurate results depend on matching the correct technique to the sample’s composition.

For catalysts, concentrates, scrap, or multi-metal blends, we apply:

- Fire assay with cupellation for accurate determination of precious metals at various concentration levels

- Wet chemistry and titration for high-precision elemental quantification

- Instrumental analysis (ICP) for trace-level PGMs and multi-element characterization

While XRF is useful for screening, it is rarely sufficient for commercial-grade settlement values due to its limited sensitivity for PGMs.

Our Lab’s Capabilities And Accreditation

Ledoux & Co. is ISO 17025 accredited confirming our technical competence and the validity of our results. We are also ISO 9001:2015 certified, reinforcing our quality-management discipline across every step of our workflow.

Since 1880, clients have relied on our consistency, precision, and scientific rigor. Our work incorporates controlled instrumentation, robust QC procedures, and NIST-traceable reference materials to ensure repeatable, defensible measurements.

Workflow For A Recovery Client

Our workflow is structured for clarity, traceability, and efficiency. Clients follow a standard path:

- Sample submission

- Material preparation

- Method selection based on material type

- Detailed analysis

- Clear, independent reporting

We also provide On-Site Services for Precious Metals when needed. Clients use our results to negotiate refining contracts, validate supplier claims, or verify settlement values. We emphasize consistent turnaround times and reproducible data to support high-value decision-making.

Maximizing Return from Your Materials

Our goal is simple: help clients capture the full worth of their materials.

How Accurate Assay Reports Help You Get The Most Value

Accurate assays strengthen contract negotiations by providing verified data on metal content. They reduce loss from incomplete or uncertain results and offer benchmarking opportunities that help clients evaluate material sources and refinery performance.

Reliable, audit-ready documentation ensures full transparency and improves long-term financial outcomes.

Case Considerations: Scrap Catalyst, Electronic Scrap, Concentrates

Our experience spans multiple material types, each requiring different analytical approaches:

- Spent automotive catalyst: We measure Pt, Pd, and Rh with proven reliability.

- Electronic scrap: High-value metal streams require trace-level sensitivity and specialized handling.

- Concentrates and ores: Both bulk and trace elements must be characterized accurately for settlement and valuation.

Value-Added Services And Partnership Approach

Our on-site representation mitigates risk at critical recovery steps. As an independent laboratory with no commercial interest in the material, we provide unbiased results that represent our clients’ best financial interest.

Photo: Vecteezy

We treat each sample with the diligence we would apply to our own material. Many clients incorporate our data into procurement workflows, quality systems, and contract negotiations to strengthen their operational and financial decisions.

Choosing the Right Partner for Precious Metals Recovery

A qualified laboratory ensures your material is handled correctly and your results support key business outcomes.

Key Criteria To Consider When Selecting A Lab Or Recovery Partner

Organizations evaluating precious metals recovery partners should begin by considering accreditation and technical competence.

Key factors include:

- Accreditations: ISO 17025 and ISO 9001

- Experience with PGMs: Proven capability across catalysts, scrap, ores, and concentrates

- Transparent methodology: Full documentation and traceability

- On-site representation: Oversight during sampling and weighing

- Independence: Unbiased commercial-grade reporting

Why Ledoux & Co. Stands Apart

Metallurgical testing laboratory like Ledoux & Co. is an independent, family-owned organization with more than 140 years of experience serving clients worldwide, from Fortune 500 companies to specialized firms. Our proven expertise spans precious metals, catalysts, electronic scrap, and on-site representation.

We deliver commercial-grade assay results that support financial transactions and settlement negotiations. Our commitment to accuracy, integrity, and scientific clarity sets us apart in the industry.

Contact us to discuss your materials and precious metals recovery objectives. Submit your sample and let our team develop the right analysis approach for your needs.