In the world of precious metals, a tiny miscalculation in weight or an unrepresentative sample can result in thousands of dollars lost, strained relationships, or even legal disputes. Whether you’re a refiner, recycler, or trader, you know that trust must be earned and verified.

That’s where onsite precious metal verification testing comes in.

By combining onsite weighing, representative sampling, and independent oversight, this service ensures that every gram of material is accounted for before it changes hands. For businesses working with high-purity metals, onsite verification creates a layer of protection against human error, bias, or inconsistency.

What Is Onsite Precious Metal Verification Testing?

Onsite precious metal verification testing is the process of evaluating metal materials at the client’s location before they are moved, refined, or sold. It involves three core activities: accurate weighing, representative sampling, and independent oversight.

A trained metallurgical representative from an accredited lab like Ledoux & Co. arrives on-site to observe and document every step. They inspect the material, verify the weight using calibrated equipment, and ensure that the sampling process adheres to industry best practices.

The result is a chain of custody backed by impartial documentation and peace of mind, knowing that your high-value material has been properly represented from the very beginning.

The Value Of Onsite Weighing And Sampling For Precious Metals

In the precious metals industry, accurate weighing and sampling are the first steps to a fair payout. These aren’t routine tasks, they set the foundation for every analysis, trade, and settlement that follows.

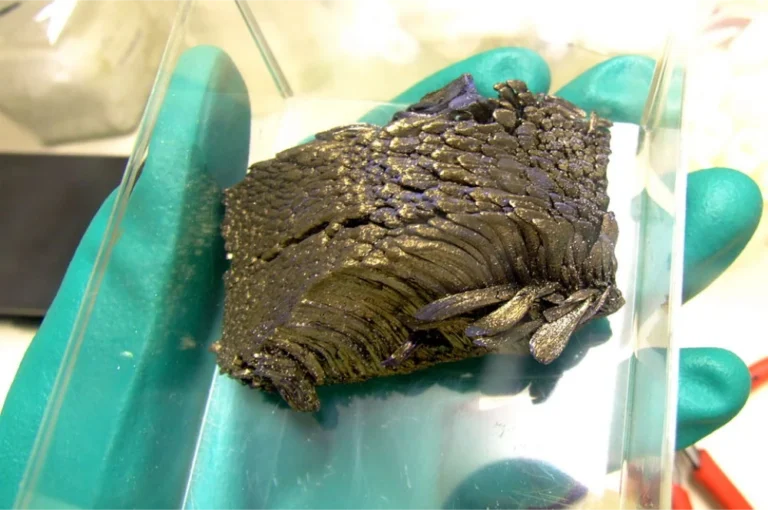

Using calibrated, NIST-traceable scales and proper sampling techniques ensures the results reflect the true value of the material. This is crucial for complex materials like e-scrap, catalysts, or alloys where uneven composition can distort results.

Onsite verification also prevents tampering, loss, or sampling bias. When a representative is present to document each step, the process becomes transparent, traceable, and trusted by all parties.

How Assay Accuracy Depends On Proper Sampling

Even the best lab can’t fix a poorly drawn sample. Accurate precious metal assays start with proper onsite sampling that truly reflects the entire batch. Skipping this step risks inconsistent results and undervalued payouts.

Professional technicians follow strict protocols to account for moisture, particle distribution, and residue—small factors that can lead to big errors. When sampling is done right, results from fire assay, ICP, or wet chemistry are more precise, defensible, and trusted in commercial and legal settings.

For high-value materials, accurate onsite verification removes doubt and protects your bottom line.

Independent Onsite Representation: A Critical Safeguard

When precious metals are involved, relying only on internal teams or third parties with vested interests can create unnecessary risk. Independent onsite representation isn’t a luxury, it will be a safeguard for transparency and trust.

At Ledoux & Co., we act as neutral third-party observers during metal weighing and sampling procedures. Our team is not involved in the sale, purchase, or transportation of the material. Our only interest is accuracy. That independence provides a layer of credibility and transparency that’s vital in high-value transactions.

What clients receive:

- Verified documentation of weights and sampling methodology

- Onsite witness of container opening, weighing, and sample drawing

- Real-time dispute resolution by trained professionals

- Traceable records that support financial and legal accountability

For clients in refining, recycling, or trading, where even fractions of an ounce can mean thousands of dollars, this level of oversight helps eliminate ambiguity and prevent costly conflicts.

Ledoux’s commercial-grade assays and field documentation are trusted for financial settlements. Our representatives become an extension of your own quality assurance program, with the independence and rigor only a 140-year-old laboratory can deliver.

When Should You Use Onsite Precious Metal Verification?

Not every transaction calls for third-party oversight. But when it involves high-value, high-purity materials, onsite precious metal verification is a smart, proactive step.

Common scenarios include:

- Material handoffs at refineries or smelters

- Precious metal recycling or e-scrap processing

- Trade or ownership transfers

- Customs or international shipping checkpoints

These services are especially valuable for recyclers, refiners, smelters, metal buyers, and industrial manufacturers. These businesses routinely handle materials where every percentage point of metal content matters.

With fast dispatch and national reach, Ledoux & Co. brings independent assurance right to your loading dock, lab, or facility floor.

Independent Testing Is the Foundation of Trust

Whether you’re transferring materials, preparing for refining, or negotiating high-stakes transactions, onsite precious metal verification gives you the confidence that what you’re trading is exactly what it claims to be. No shortcuts. No surprises.

With Ledoux & Co. as your independent verification partner, you gain more than just a service. You gain clarity, protection, and peace of mind backed by over a century of metallurgical precision.

Ready to protect your investment?

Submit a sample or contact us today to speak with a representative.