What ruthenium is used for centers on its role as a high-performance catalyst, electronic material, and alloying element in advanced industrial systems. This platinum group metal is valued for durability, chemical stability, and catalytic efficiency.

Understanding what ruthenium is used for helps companies assess material value, recovery potential, and analytical requirements. At Ledoux & Co., we deliver ISO 17025–accredited analysis for ruthenium-bearing materials.

What Ruthenium Is Used For In Industrial Catalysts

Across refining, chemicals, and energy systems, what ruthenium is used for reflects its ability to improve selectivity, durability, and overall process economics.

Ruthenium As A Catalyst Metal

Ruthenium delivers high catalytic activity at low loadings, making it economically efficient despite its scarcity. It resists thermal degradation and chemical poisoning, allowing longer catalyst life in harsh environments.

Ruthenium also functions effectively under high pressure and temperature, often acting as a promoter that enhances the performance of other PGMs. Because it is frequently present at trace levels, precise analytical techniques are essential.

Key Industrial Catalyst Applications

In petroleum refining, ruthenium is used in hydrocracking, reforming, and hydrogenation to improve selectivity and efficiency with complex feedstocks.

In chemical manufacturing, it supports ammonia, methanol, and fine chemical synthesis while enabling cleaner reaction pathways.

Pharmaceutical and specialty chemical processes rely on ruthenium catalysts for high selectivity and purity. Ruthenium also plays a growing role in electrochemical and hydrogen-related catalysts tied to energy transition technologies.

Why Catalyst Testing Matters

Ruthenium content directly influences catalyst valuation and recycling decisions.

Spent catalysts often contain recoverable ruthenium alongside other precious metals. Accurate testing is required for financial settlements, refining strategies, and dispute resolution.

Due to complex matrices, ICP-based and wet chemistry methods are required rather than surface-level screening.

Ruthenium In Electronics And Electrical Applications

What ruthenium is used for in electronics is ensuring long-term electrical stability and reliability as devices become smaller and more complex.

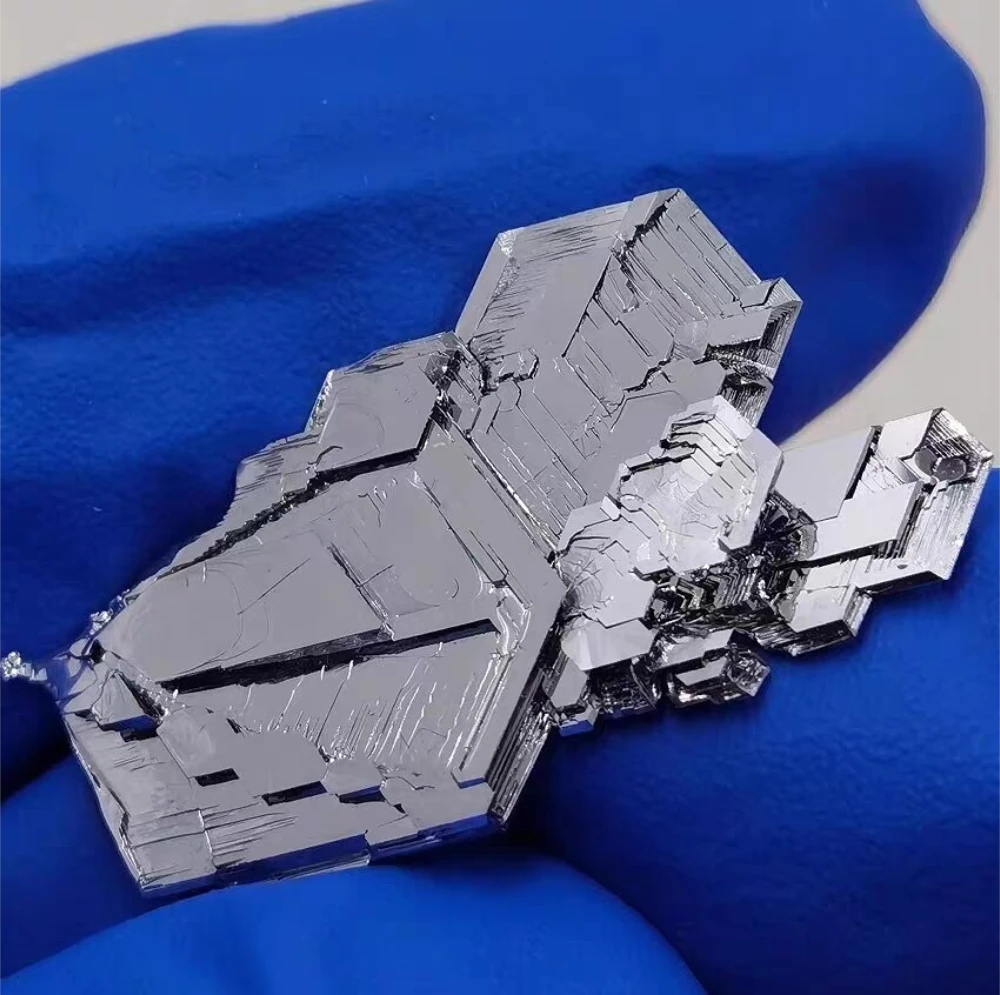

Electrical And Physical Properties Of Ruthenium

Ruthenium offers high electrical conductivity and exceptional oxidation resistance, even as thin films. It maintains stable performance through repeated thermal cycling and supports miniaturization without degradation, making it suitable for advanced electronic manufacturing.

Common Electronic Uses

Ruthenium oxide films are widely used in chip and thick-film resistors due to their stable resistance values.

In semiconductor manufacturing, ruthenium functions as a diffusion barrier and is used in memory and logic devices.

Hard disk drives apply thin ruthenium coatings to reduce wear and enhance data reliability. Specialty components rely on ruthenium where long-term electrical stability is critical.

Importance For E-Scrap And Recycling

Ruthenium typically occurs at very low concentrations and is embedded within complex assemblies.

Accurate detection requires complete digestion and ICP-OES or ICP-MS analysis. When aggregated at scale, recoverable ruthenium contributes meaningful economic value.

What Ruthenium Is Used For In Alloys And Surface Coatings

What ruthenium is used for in alloying is enhancing mechanical performance and durability without compromising precision.

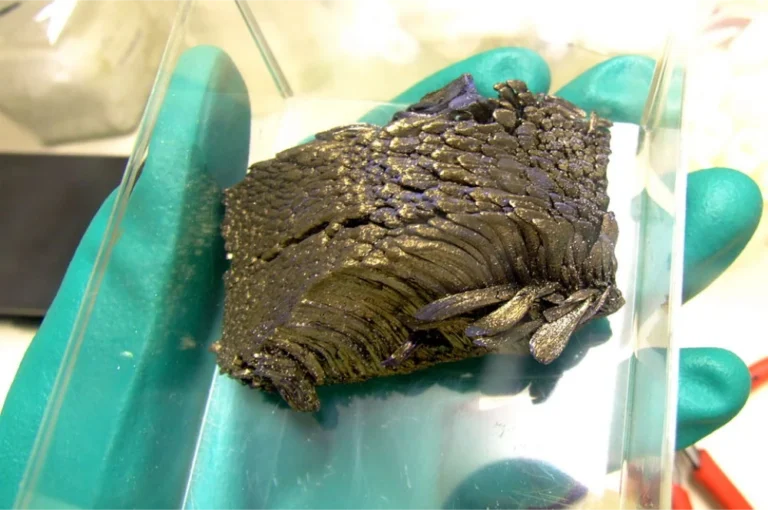

Why Ruthenium Is Added To Alloys

Minor ruthenium additions significantly increase hardness and wear resistance. It improves corrosion resistance in aggressive environments and enhances high-temperature strength.

Ruthenium also stabilizes grain structure in precious metal alloys, reducing deformation and extending service life.

Key Alloy And Coating Applications

Platinum and palladium alloys use ruthenium to improve durability in laboratory and industrial equipment. Electrical contacts benefit from low contact resistance and long service life.

Aerospace and precision instruments rely on ruthenium for dimensional stability. Thin surface coatings reduce friction and wear where long-term reliability is required.

Impact On Manufacturing And Quality Control

Minor compositional changes in ruthenium-bearing alloys can significantly affect performance and service life. Accurate alloy verification ensures compliance with specifications, predictable material behavior, and reduced production risk.

For high-value materials, commercial-grade assays are essential to support quality control, customer confidence, and contractual obligations.

How Ruthenium Supports Energy And Environmental Technologies

What ruthenium is used for in energy systems is enabling efficient, durable reactions that support cleaner technologies.

Energy-Related Applications

Ruthenium is used in catalysts for hydrogen production and purification, supporting cleaner fuel pathways. In fuel cells, it facilitates key electrochemical reactions required for efficient energy conversion.

The metal also enhances water splitting and electrolysis processes by improving electrode efficiency and durability. These applications position ruthenium as a contributor to next-generation energy infrastructure.

Chemical Stability Advantages

Ruthenium resists corrosion in both acidic and alkaline environments, a critical advantage for energy and environmental systems. It maintains catalytic activity over extended operating periods, reducing downtime and replacement frequency.

This durability translates directly into lower operating costs and improved system reliability.

Commercial And Strategic Implications

Demand for ruthenium is increasingly linked to energy transition and decarbonization initiatives. Much of the supply is recovered from spent catalysts and industrial residues, making accurate analysis essential.

Reliable data supports proper valuation, efficient recovery planning, and compliance with regulatory and contractual requirements.

How We Analyze Ruthenium At Ledoux & Co.

What ruthenium is used for directly informs how it must be accurately measured, especially when present at trace levels in complex materials. At Ledoux & Co., our analytical approach is designed for commercial decision-making.

Our Analytical Capabilities

We operate an ISO 17025–accredited precious metals laboratory delivering independent, high-accuracy results. Our analytical techniques include ICP-OES, ICP-MS, wet chemistry, and fire assay when applicable.

All work is supported by strict QA/QC protocols using NIST-traceable standards to ensure data integrity and repeatability.

Materials We Commonly Test

We routinely analyze spent and fresh industrial catalysts, electronic scrap and residues, precious metal alloys and concentrates, and mixed or complex industrial materials containing trace PGMs.

Why Partner With Ledoux & Co.

Our results are independent and unbiased, suitable for financial settlements, umpire analysis, and control samples. With more than 145 years of metallurgical expertise, we are trusted by global manufacturers, refiners, and recyclers to deliver commercial-grade data with confidence.

Key Takeaways

Ruthenium supports critical applications across catalysts, electronics, alloys, and energy systems. Its value often resides in trace concentrations within complex materials. Accurate, ISO-compliant testing is essential for informed commercial decisions.

At Ledoux & Co., we deliver trusted, commercial-grade ruthenium analysis. Partner with us to reduce risk and gain confidence in your data.

FAQs

Understanding what ruthenium is used for often raises practical and commercial questions. The following FAQs address common considerations related to analysis, recovery, and valuation.

1. Is ruthenium considered a precious metal?

Yes. Ruthenium is a platinum group metal valued for scarcity, performance, and industrial importance rather than jewelry demand.

2. How does ruthenium differ from platinum or palladium?

Ruthenium offers higher hardness and unique catalytic behavior, often as a promoter rather than a primary metal.

3. Does ruthenium affect alloy certification?

Yes, even small amounts can significantly influence performance. Accurate verification is essential for meeting specifications and quality standards.

4. Why use an ISO 17025–accredited lab for ruthenium analysis?

Accreditation ensures validated methods, traceability, and defensible results suitable for commercial and regulatory use.