Palladium mining is becoming harder due to rising costs and shrinking deposits. Recycling has become the best way to meet demand. Since 2000, over 67 tonnes of palladium have come from catalytic converter recycling.

Finding and processing palladium scrap is now a key way to recover this valuable metal. Whether you’re an individual collector or a business, knowing where to look and how to process scrap can help you get the best value.

Where to Find Palladium Scrap?

Palladium is in many everyday and industrial products. Recycling these materials helps recover and reuse the metal efficiently. Here are the top sources of palladium scrap.

Auto-Catalysts

Catalytic converters are one of the top sources of palladium scrap. Honeycomb structures in these devices are coated with palladium. Carbon monoxide and nitrogen oxides are broken down in vehicle emissions.

The metal helps speed up chemical reactions, making exhaust gases safer. When cars are scrapped, converters hold valuable palladium that can be extracted and reused.

With over 27 million vehicles retired worldwide each year, catalytic converter recycling remains a steady supply for palladium recovery.

Dental Materials

Palladium is used in dental crowns, bridges, and inlays. It is often mixed with gold or platinum for precise shaping and longevity. When replacements are made, old dental work is discarded. Grindings, sprues, and failed castings contain recoverable palladium.

Even a single crown can contain up to 0.5 grams of the metal. Refining companies accept dental scrap and extract the palladium content. They ensure that these materials are repurposed rather than wasted.

Pharmaceutical Catalysts

Palladium is used to make antibiotics, cancer drugs, and antiviral medicines. It helps start chemical reactions during production. Over time, these catalysts wear out and need replacing.

Instead of throwing them away, companies can recycle them. Used catalysts, filter residues, and reactor coatings all contain palladium. Refining can recover several ounces from a single batch. This lowers costs and keeps the metal available for future drug production.

Medical Testing Devices

Palladium is used in medical testing devices, including electrodes, biosensors, and diagnostic tools. Its high conductivity helps blood analyzers and heart monitors give accurate readings.

As technology advances, many of these devices reach the end of their lifespan. Instead of being wasted, old devices can be sent to specialized refiners. Palladium is extracted and reused in new medical tools. This reduces reliance on fresh mining.

With lower costs and valuable materials kept in circulation, recycling supports both healthcare and sustainability.

Jewelry & Decorations

Palladium shines in fine jewelry with its bright white color and lightweight feel. It’s a top choice for rings, wedding bands, and luxury watches. Unlike white gold, it stays bright without plating. High-end brands use it in brooches, cufflinks, and premium pen casings.

Old jewelry and designer accessories hold hidden value. Even decorative art pieces may contain palladium. Refining these items recovers the metal for new creations. This process reduces waste and keeps palladium in use.

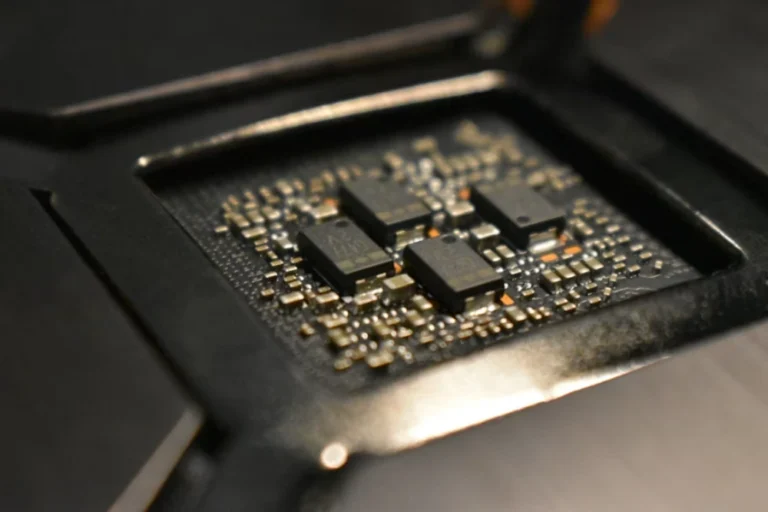

Electronics

Palladium is crucial in electronics, enhancing circuit boards, connectors, and sensor contacts. It helps signals travel fast in phones, laptops, and medical devices. Many chips need palladium plating to work well.

Old phones, computers, and TVs contain trace amounts of palladium. Though small per device, large-scale recycling recovers valuable quantities. Specialized e-waste processors extract and refine the metal. This keeps palladium in circulation, reducing the need for new mining and supporting sustainable tech production.

If you’re unsure how to test palladium found in electronic scrap, certified labs like Ledoux can analyze the content with precision.

Palladium Alloys Used for Manufacturing

Palladium alloys play a key role in aerospace, chemical processing, and precision engineering. They enhance turbine components, reactor parts, and specialized tools. Many industries depend on them for protective coatings and durable machinery.

During production, scrap metal builds up from machining and defective parts. Old equipment may also contain recoverable palladium. These materials are refined to recover the metal for reuse. Costs are reduced, and reliance on new mining decreases. Palladium is kept in circulation, supporting sustainable manufacturing.

What Are the Steps to Process Scrap Palladium?

Recycling palladium involves several steps to separate and purify the metal. The basic process includes:

- Separation – Palladium-containing materials are sorted from other waste.

- Milling – The materials are crushed into smaller pieces.

- Acids – Chemical treatments dissolve impurities and separate the palladium.

- Extraction – Methods like precipitation or electrolysis remove the palladium from the solution.

- Melting – The extracted palladium is heated to remove remaining impurities.

- Pouring – The purified palladium is cast into bars or granules for reuse or resale.

Waste is reduced, sustainability is supported, and a steady supply of this valuable metal is ensured by processing scrap palladium.

Get the best value for your palladium scrap from electronic with precise analysis. With Ledoux & Company, you’ll know exactly how much your material is worth, ensuring you receive top dollar. Our ISO 17025-accredited testing gives you accurate results you can trust, so you never leave money on the table.

Whether you’re unsure how to test palladium from medical devices or wondering where can I find palladium in legacy manufacturing scrap, Ledoux provides clarity and confidence. Backed by decades of expertise, Ledoux helps businesses and recyclers maximize returns with precision and integrity.

Maximizing Your Palladium Scrap Returns with Ledoux

Recycling palladium keeps this rare metal in use, reduces mining demand, and supports industries that rely on it. Palladium scrap from catalytic converters, dental materials, electronics, or manufacturing can be refined. This process ensures maximum value.

Ledoux & Company offers metal testing with ISO 17025 accreditation. This testing shows the exact palladium content in your materials. Our advanced methods eliminate guesswork, helping you secure the best payout. With decades of expertise, Ledoux is a trusted partner for businesses and recyclers looking to maximize returns with confidence.

Get an accurate valuation with Ledoux & Company today!